Precision casting with excellent quality

Integrated research and development, manufacturing, sales, and technical services of laboratory scientific instruments and intelligent equipment

National Consultation Hotline 15738867410

Integrated research and development, manufacturing, sales, and technical services of laboratory scientific instruments and intelligent equipment

National Consultation Hotline 15738867410

15738867410

Greenland Binhu International City (District 1), Erqi District, Zhengzhou City, Henan Province

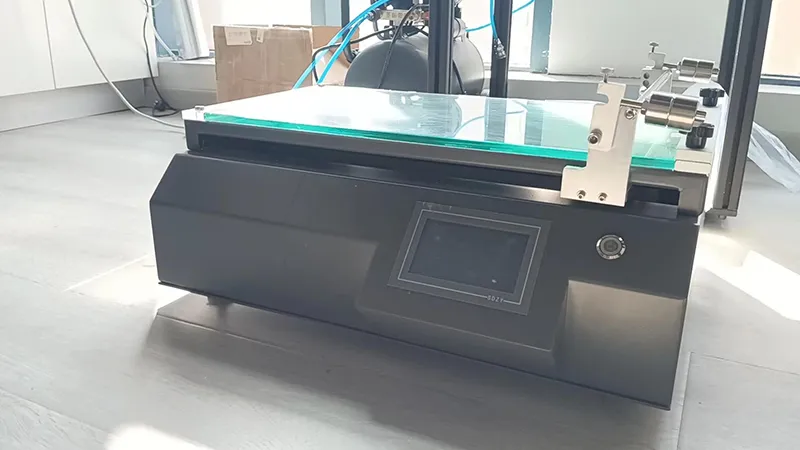

FLAT COATING MACHINE

PRODUCT DESCRIPTION

This equipment is designed specifically for high-precision coating processes in laboratories, using a modular integrated structure that is easy to operate and has strong stability. The core function is to achieve uniform coating of liquid/semi liquid materials (such as photoresist, battery slurry, nano coatings, biological reagents, etc.) on the substrate surface through precise movement of the coating head at room temperature or controllable temperature environment. The types of substrates that can be processed include:

·Glass/quartz plates (used for optical device preparation);

·Silicon/ceramic wafers (used for semiconductor/electronic component manufacturing);

·Flexible substrates (such as PET and PI films, suitable for the field of flexible electronics);

·Metal foil materials (such as aluminum foil, copper foil, used for coating battery electrodes).

The equipment is suitable for preparing various functional coatings, such as:

·Microelectronics field: integrated circuit photoresist coating, MEMS device insulation dielectric layer;

·In the field of new energy: coating of positive and negative electrode slurry for lithium-ion batteries, electrolyte coating for solid-state batteries;

·In the field of optics: coating of optical thin film precursors, preparation of nano anti reflective coatings;

·Biomedical field: drug loaded coating, biosensor sensitive film coating.

PRODUCT FEATURES

1. High precision coating performance

·Coating head motion control: Using servo motor driven linear guide rail, the coating speed can be controlled between 0.1-200 mm/s, with a positioning accuracy of ± 0.01 mm. It supports linear coating, curved coating, and grid array coating modes.

·Controllability of coating thickness: By adjusting the distance between the coating head and the substrate (adjustable from 0.1-500 μ m), slurry viscosity, and movement speed, precise control of coating thickness from nanometer to micrometer (50 nm-500 μ m) can be achieved, with a uniformity error of less than 3%.

2. Intelligent Process Control System

·Full process automation: equipped with PLC programmable controller, supports custom coating parameters (such as coating path, speed, number of times, gap time, etc.), can store more than 50 sets of process programs, and automatically completes substrate positioning, coating, drying (optional) and other processes after one click start.

·Environmental parameter monitoring: Equipped with temperature sensors (room temperature -150 ℃, accuracy ± 1 ℃) and humidity sensors (accuracy ± 2% RH), supporting real-time monitoring and closed-loop control of the coating environment to ensure process stability.

3. Flexible scalability

·Multi coating head compatibility: standard configuration of precision bar coating head and scraper coating head, optional configuration of slit coating head, comma roller coating head or spray coating head, to meet the coating requirements of different materials (high viscosity slurry, low viscosity solution).

·Substrate size adaptability: Supports a substrate size range of 10 mm × 10 mm to 300 mm × 300 mm, equipped with a vacuum adsorption platform (adjustable suction) to ensure that the substrate is fixed without displacement during the coating process.

4. Humanized design and safety guarantee

·Visual operation interface: equipped with a color touch screen, real-time display of coating speed, position, temperature, vacuum degree and other parameters, supporting historical data storage and USB export functions.

·Safety protection mechanism: equipped with emergency stop button, protective fence for moving parts, leakage overload protection and other functions to ensure the safety of operators; The coating chamber can be equipped with a ventilation module to reduce the accumulation of volatile gases.

·Maintenance convenience: The coating head adopts a quick detachable design, and cleaning and replacement can be completed within 5 minutes; The waste liquid collection tank is a drawer type structure, which is easy to clean quickly.

5. Optional upgrade module

·Online detection component: can be equipped with a laser thickness gauge (accuracy ± 1%) or a micro vision system to monitor coating thickness and uniformity in real time;

·Heating/Cooling Platform: The substrate platform supports a temperature range of -20 ℃ to 150 ℃ with an accuracy of ± 0.5 ℃, suitable for temperature sensitive material coating;

·Automatic feeding system: equipped with precision metering pump (flow accuracy ± 0.1%), supporting continuous feeding or pulse dispensing coating, reducing manual intervention.

TYPICAL APPLICATION SCENARIOS

1. Semiconductor manufacturing: coating photoresist on 8-inch silicon wafers for integrated circuit patterning processes;

2. New energy research and development: coating lithium iron phosphate slurry on the surface of aluminum foil to prepare positive electrode sheets for lithium-ion batteries;

3. In the field of flexible electronics: coating silver nanoink on PI flexible substrates to prepare conductive circuits for wearable devices;

4. Preparation of optical devices: Coating titanium dioxide nano slurry on a glass substrate, sintering it to form an optical anti reflective coating;

5. Development of biosensors: Apply enzyme solution on a glass slide to prepare a sensitive detection area for a biosensor.

SUMMARY OF EQUIPMENT ADVANTAGES

·Multi functional compatibility: supports multiple coating modes (contact/non-contact), material types (solution/slurry/nanodispersion), and substrate sizes, meeting the needs of all stages from basic research to pilot production;

·High precision and repeatability: The control accuracy of key parameters (thickness, speed, temperature) reaches the industrys * * level, and the repeatability error between experimental batches is less than 3%;

·**Low consumption: adopting energy-saving driving system, energy consumption is reduced by 15% compared to traditional equipment under the same process, supporting 24-hour continuous operation;

·User friendly: The interface is simple and intuitive, supports one click process startup, and beginners can quickly master it with low maintenance costs.

QR code

Contact information

15738867410

Online Message

Top