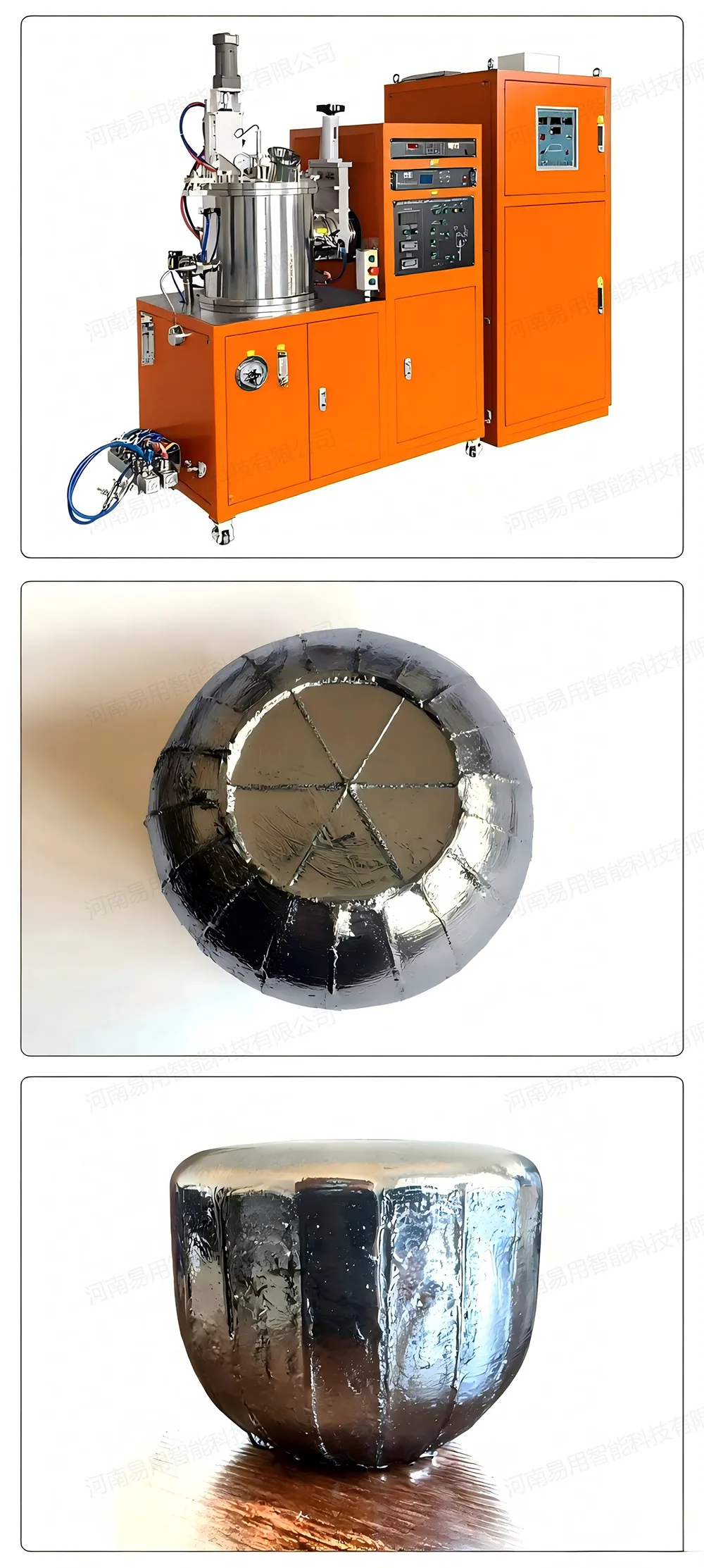

Precision casting with excellent quality

Integrated research and development, manufacturing, sales, and technical services of laboratory scientific instruments and intelligent equipment

National Consultation Hotline 15738867410

Integrated research and development, manufacturing, sales, and technical services of laboratory scientific instruments and intelligent equipment

National Consultation Hotline 15738867410

15738867410

Greenland Binhu International City (District 1), Erqi District, Zhengzhou City, Henan Province

Details

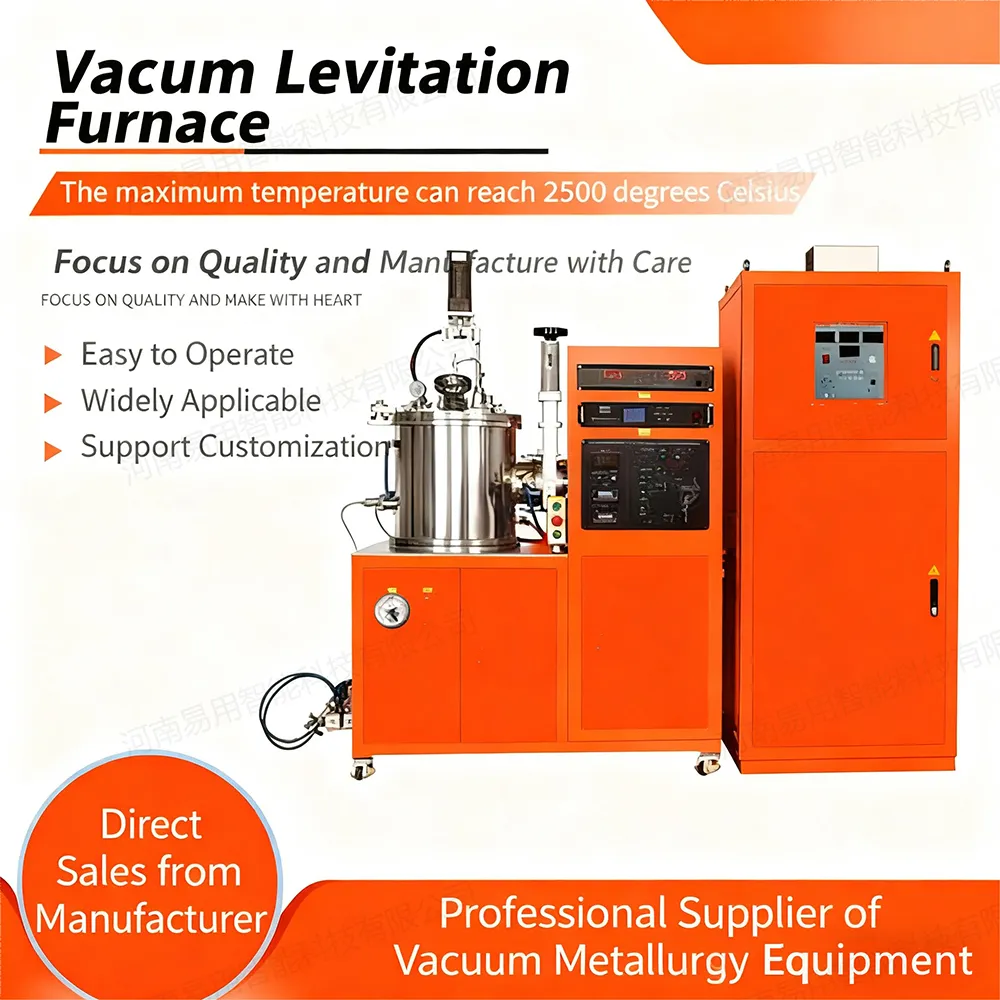

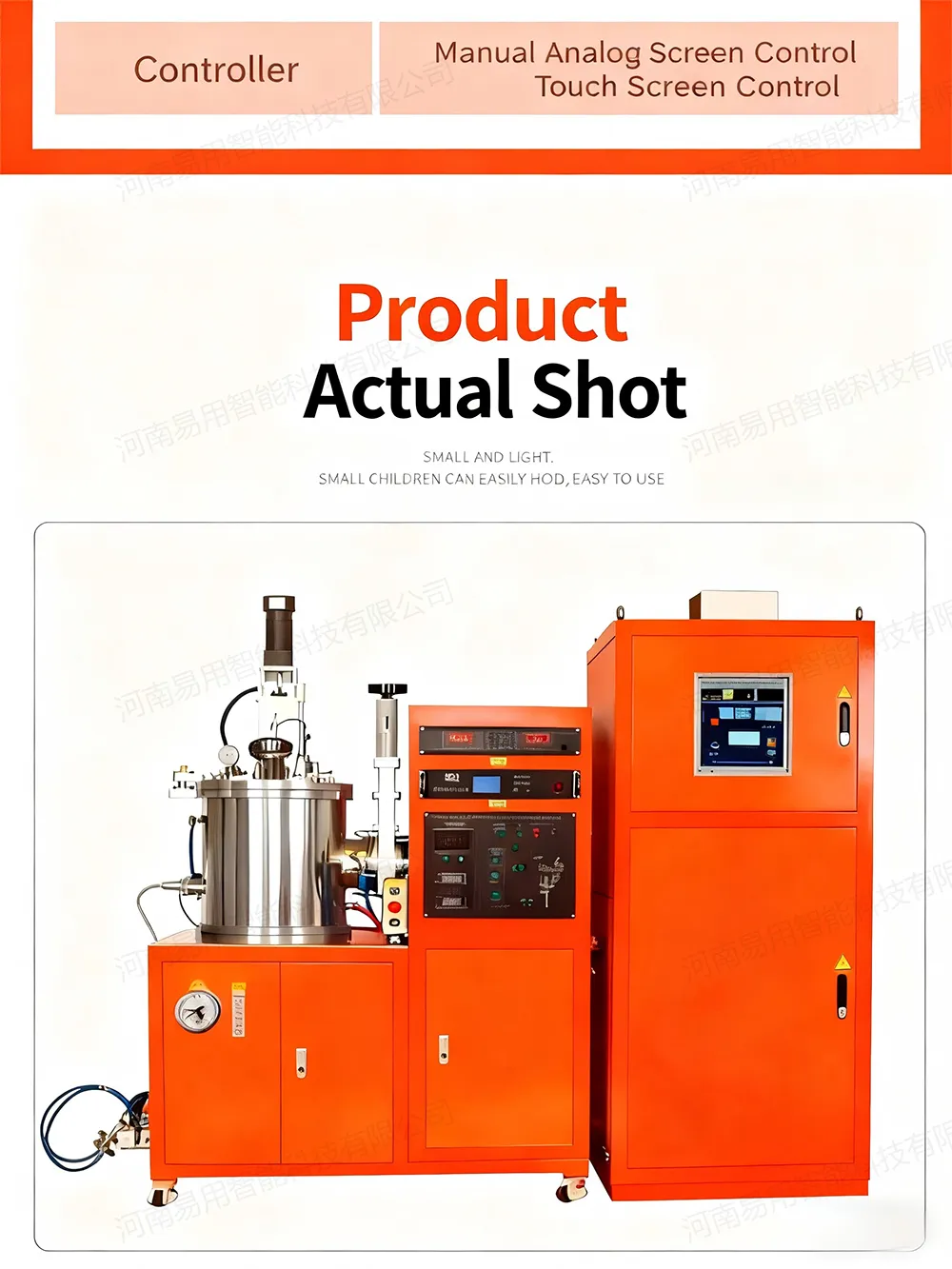

1Kg small vacuum suspension melting equipment

Brief Description:

The 1Kg small vacuum suspension melting equipment melting method is a melting method that has developed rapidly in recent years. It is mainly used to produce high-melting-point, high-purity and extremely active metals. It has been widely used in many important fields such as metallurgy and high-material preparation, showing good application prospects.

Detailed introduction:

Principle of 1Kg small vacuum suspension melting equipment

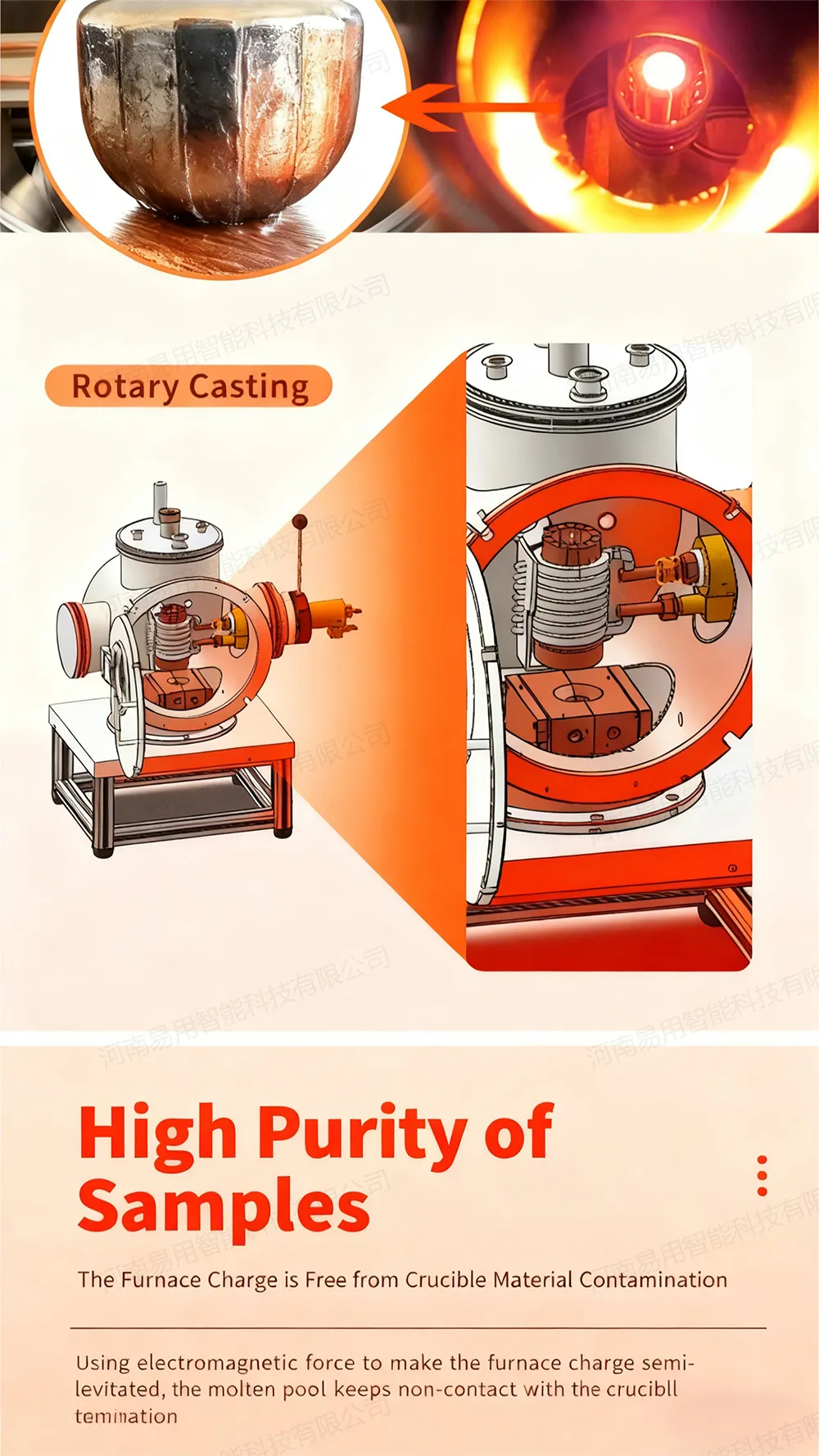

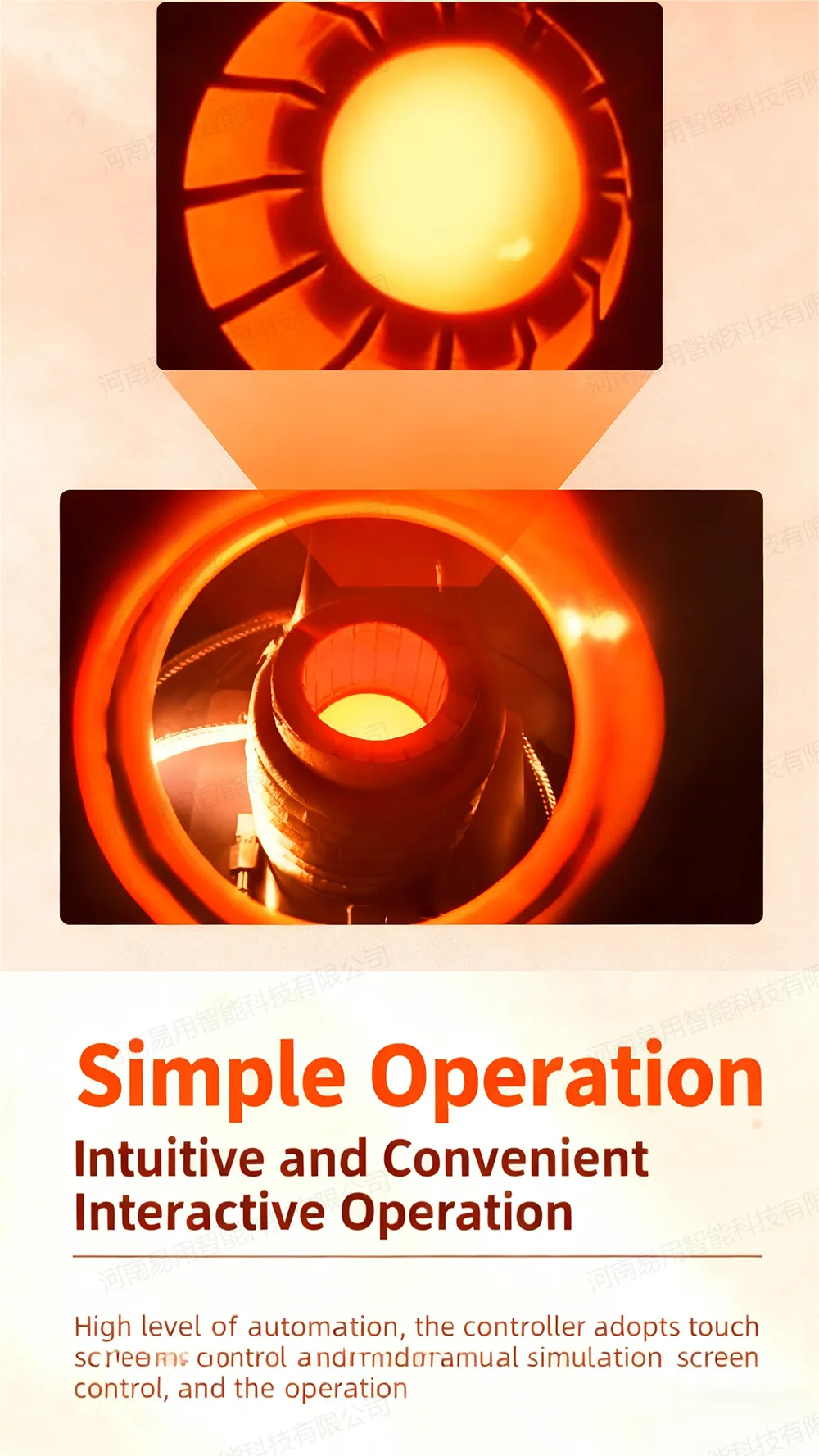

Small vacuum levitation melting equipment uses a high-frequency or medium-frequency alternating magnetic field to form an electromagnetic force that offsets gravity during metal smelting, causing the melt to suspend and separate from the inner wall of the crucible. This method is a comprehensive metallurgical technology that integrates multiple disciplines such as electromagnetism, fluid dynamics, thermodynamics, mechanics, physical chemistry, and metallurgy.

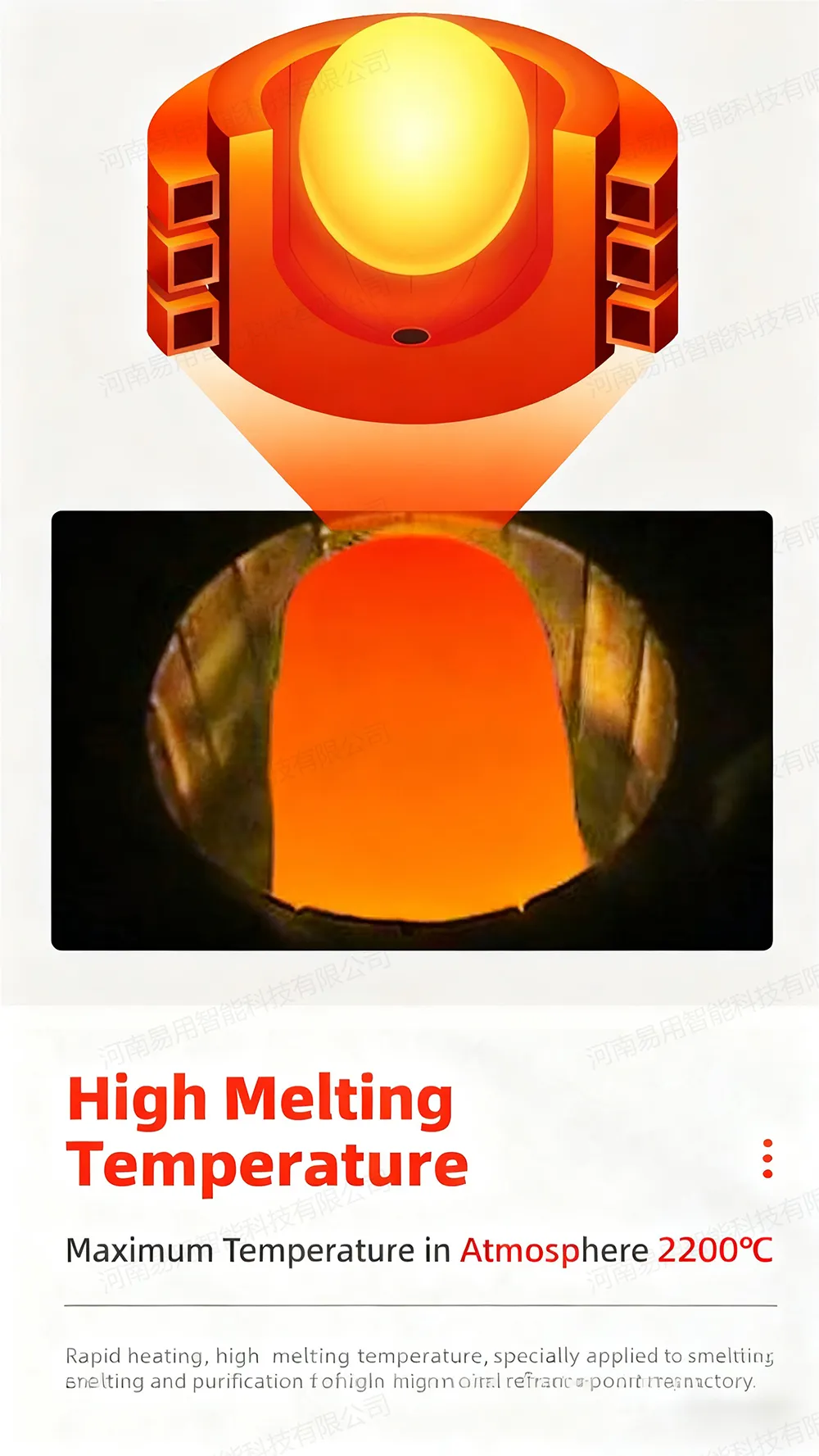

Metal materials are melted under vacuum or protective atmosphere conditions, using electromagnetic force to semi-suspend the charge. This keeps the molten pool and crucible walls out of contact, protecting the charge from contamination by the crucible material. Small vacuum levitation melting equipment is effective for melting active metals, high-melting-point metals, and their alloys. Equipped with a vacuum pump system, it extracts oxygen from the furnace chamber before heating, maintaining a pure atmosphere or vacuum environment to minimize oxygen content. The maximum temperature under this atmosphere is 2200°C.

Advantages of 1Kg small vacuum suspension melting equipment

1. Compact design meets laboratory application requirements

2. Can be smelted under various atmosphere conditions

3. Rapid heating

4. Eliminate the pollution of crucible to smelting materials

5. The alloy composition is uniform after smelting

6. The sample has high purity after smelting

7. Two casting methods are available: pot bottom forming and rotation casting

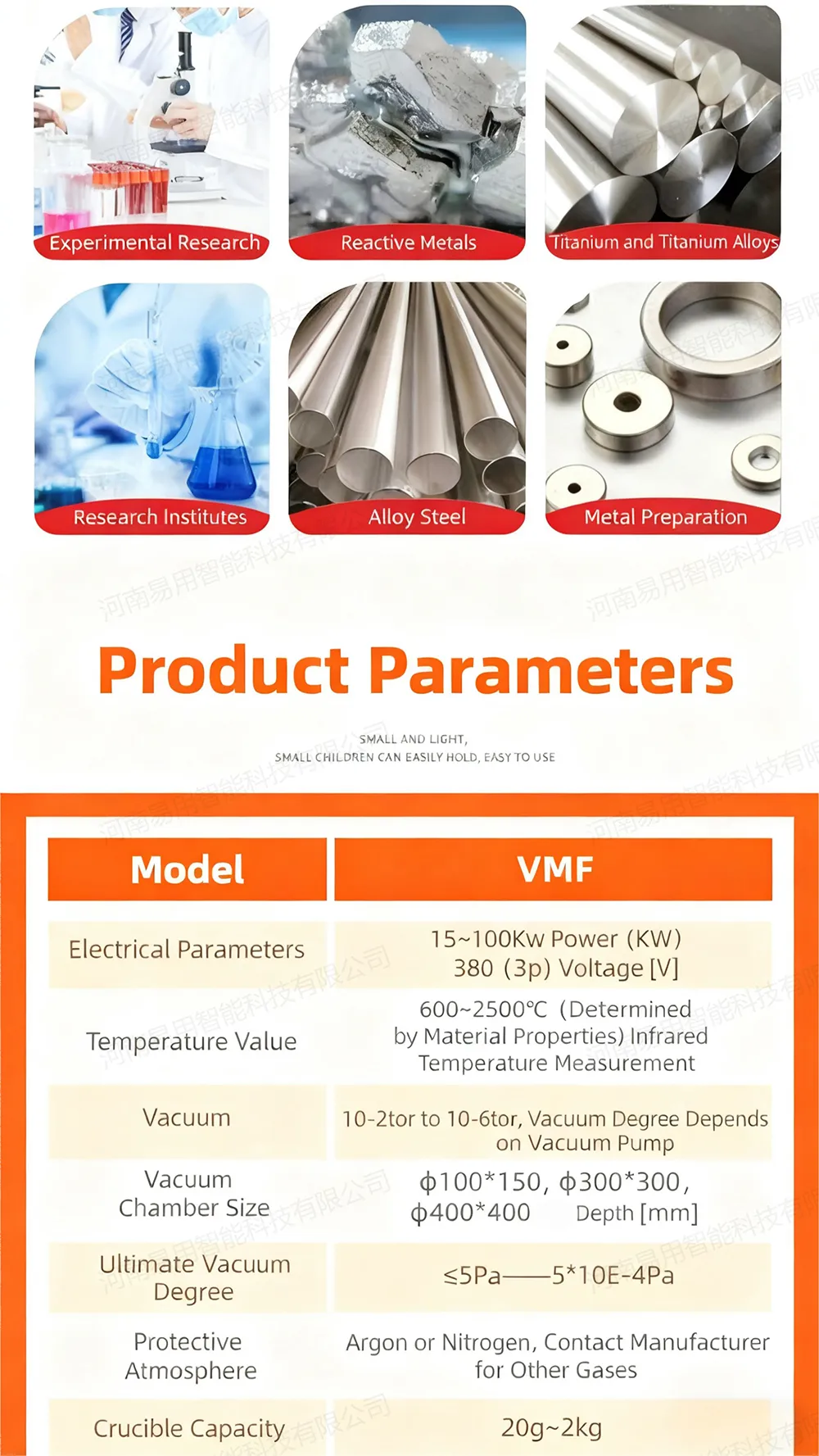

Typical Applications

1. Materials research

2. Preparation of active metals and alloys

3. Preparation of metals and alloys with particularly high purity requirements

4. Preparation of alloys and intermetallic compounds with particularly high requirements for composition accuracy

5. Preparation of refractory metals and alloys with melting points close to or exceeding 2000°C and precious metals and alloys

6. High requirements for material purity, composition accuracy and uniformity, and the expectation to exclude impurities and other。

QR code

Contact information

15738867410

Online Message

Top