Precision casting with excellent quality

Integrated research and development, manufacturing, sales, and technical services of laboratory scientific instruments and intelligent equipment

National Consultation Hotline 15738867410

Integrated research and development, manufacturing, sales, and technical services of laboratory scientific instruments and intelligent equipment

National Consultation Hotline 15738867410

15738867410

Greenland Binhu International City (District 1), Erqi District, Zhengzhou City, Henan Province

Details

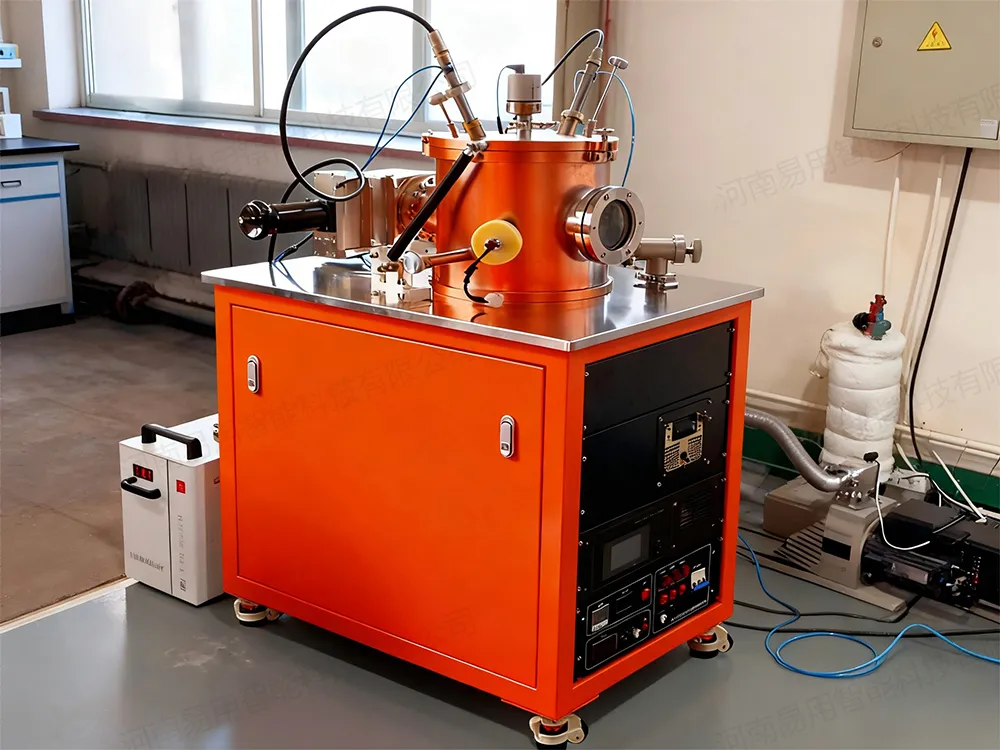

CK300 dual-target magnetron sputtering coater

1. Sputtering chamber vacuum limit: ≤6.6×10-6 Pa;

2. System vacuum leak detection rate: ≤5.0×10-7Pa.l/S;

3. The system starts to pump air from the atmosphere: the sputtering chamber can reach 6.6×10-4 Pa in 30 minutes;

4. Vacuum degree after the system stops pumping and shuts down for 12 hours: ≤5Pa;

5. One sputtering vacuum chamber, vertical top-opening structure, size not less than 300mm x 300mm, all stainless steel structure, argon arc welding, electrochemically polished surface, containing anti-fouling lining, can be baked to 100-150℃, the interface is sealed with metal gaskets or fluororubber rings, and the chamber is equipped with a lighting system;

6. Two magnetron sputtering systems, each equipped with two 50mm high-performance permanent magnet confocal magnetron sputtering targets in the sputtering chamber. Each target can operate independently, sequentially, or together. The magnetron targets are compatible with RF, DC, and MF, and can sputter magnetic materials. The distance between the magnetron targets and the substrate is adjustable, and a manually controlled baffle assembly is provided. One 500W DC power supply (minimum 500W) and one fully automatic matching RF power supply (minimum 500W) are provided. Two test targets are provided. Coating unevenness is ≤5%.

7. One rotating substrate stage, capable of holding a sample no smaller than 75mm, with continuous rotation, 0-30 rpm continuously adjustable. Substrate heating temperature: continuously adjustable from room temperature to 600°C, controlled by closed-loop thermocouple feedback. The heating power supply is equipped with a temperature controller, using PID automatic temperature control and digital display.

8. 1 set of observation window and flange interface components;

9. One set of working gas circuit, including: 100SCC mass flow controller, CF16 stop valve, pipeline, connector, etc., a total of 1 circuit; DN16 charging valve, pipeline, connector, etc., a total of 1 circuit;

10. One set of vacuum pumping unit, valves, and piping, including one compound molecular pump and variable frequency control power supply (300L/s); one mechanical pump (4L/s), one DN40 pneumatic stop valve, one set of bypass piping between the mechanical pump and the vacuum chamber, one CC100 pneumatic gate valve (for isolating the compound molecular pump from the vacuum chamber), one throttle valve, one DN40 bypass valve, and one differential pressure charging valve; the piping uses stainless steel tees and bellows.

11. Install one set of machine frame components, which are welded from high-quality square steel profiles, with the quick-release panels sprayed with plastic, and the machine surface decorated with stainless steel skin. It has four casters, which can be fixed or moved;

12. One set of vacuum measurement system, the sputtering chamber adopts imported INFICON compound meter for measurement;

13. It has the ability to alarm and implement corresponding protection measures for abnormal conditions such as water shortage, overcurrent, overvoltage, and circuit breakage of pumps, targets, and electrodes; and a complete logic program interlocking protection system;

14. The system adopts PLC + industrial computer + touch screen full-automatic control mode, which can automatically pump out gas and set programs, display and record vacuum degree and heating temperature in real time on the computer, set and display DC power supply and RF power parameters on the computer, set and display MFC setting control on the computer, and set and display the current status and sample speed on the computer.

15. Equipped with one circulating water machine, one silent air compressor, one set of special tools (including tool box), and one set of spare parts.

QR code

Contact information

15738867410

Online Message

Top