Precision casting with excellent quality

Integrated research and development, manufacturing, sales, and technical services of laboratory scientific instruments and intelligent equipment

National Consultation Hotline 15738867410

Integrated research and development, manufacturing, sales, and technical services of laboratory scientific instruments and intelligent equipment

National Consultation Hotline 15738867410

15738867410

Greenland Binhu International City (District 1), Erqi District, Zhengzhou City, Henan Province

Details

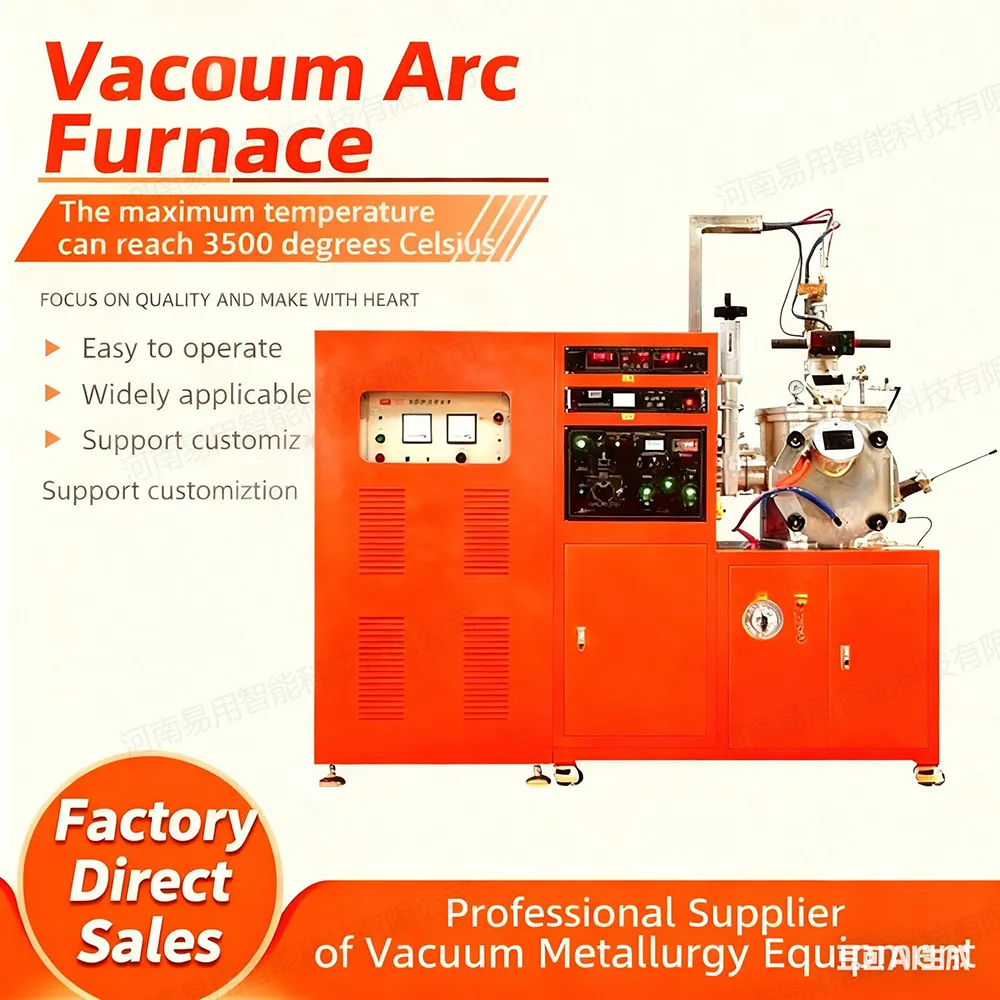

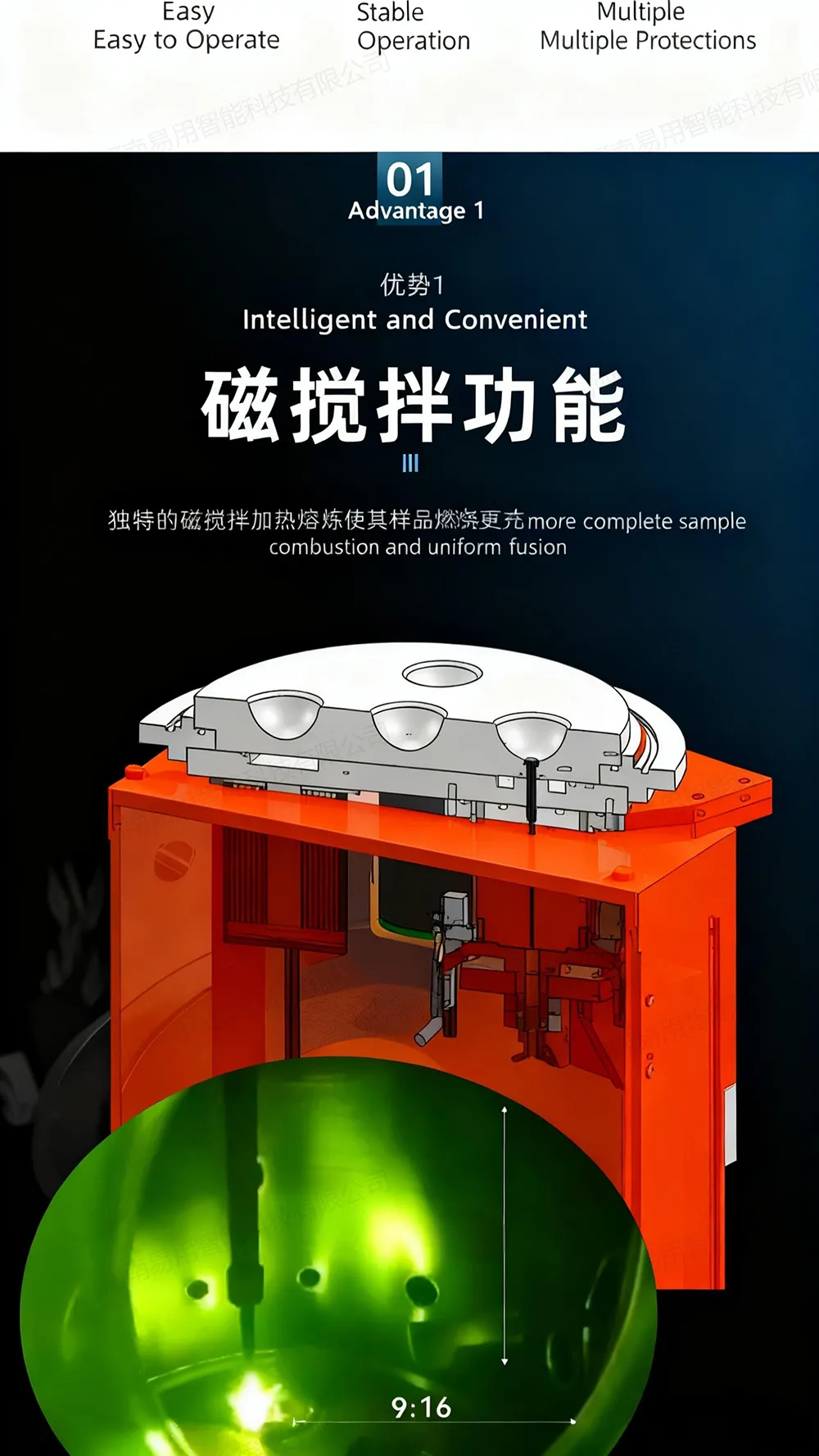

Vacuum arc melting furnace

Brief Description:

Vacuum arc melting furnaces are mainly used by colleges, universities, and scientific research institutions to melt small amounts (tens to hundreds of grams) of precious metals, alloy materials, high-melting-point materials, and refractory metals under vacuum or protective atmosphere. Arc discharge is used to heat and melt the metal raw materials to form alloys.

Detailed description:

Equipment Principle

Vacuum arc melting furnace , also called vacuum non-consumable arc melting furnace, button furnace, etc., is suitable for scientific research and development of new materials.

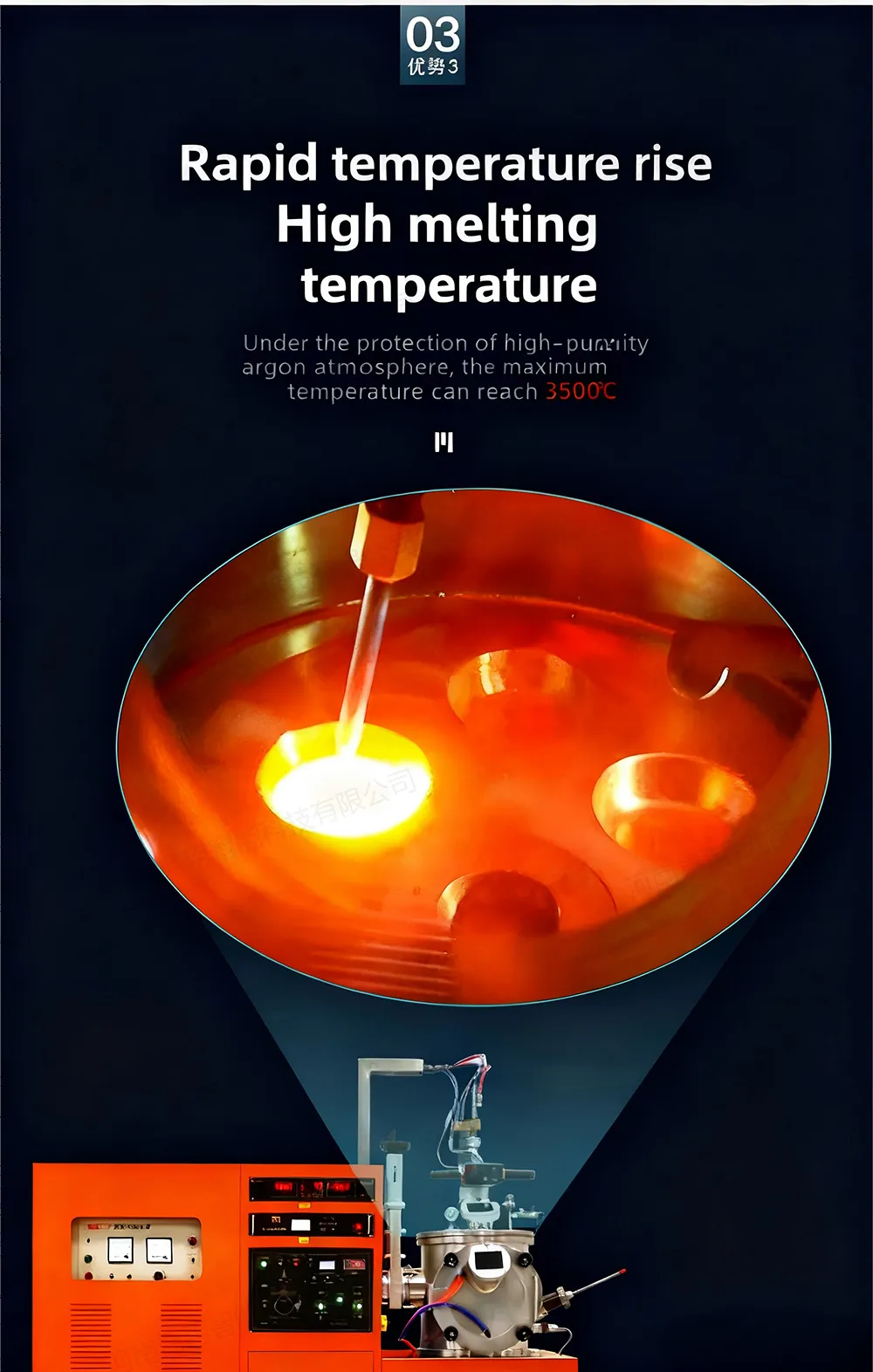

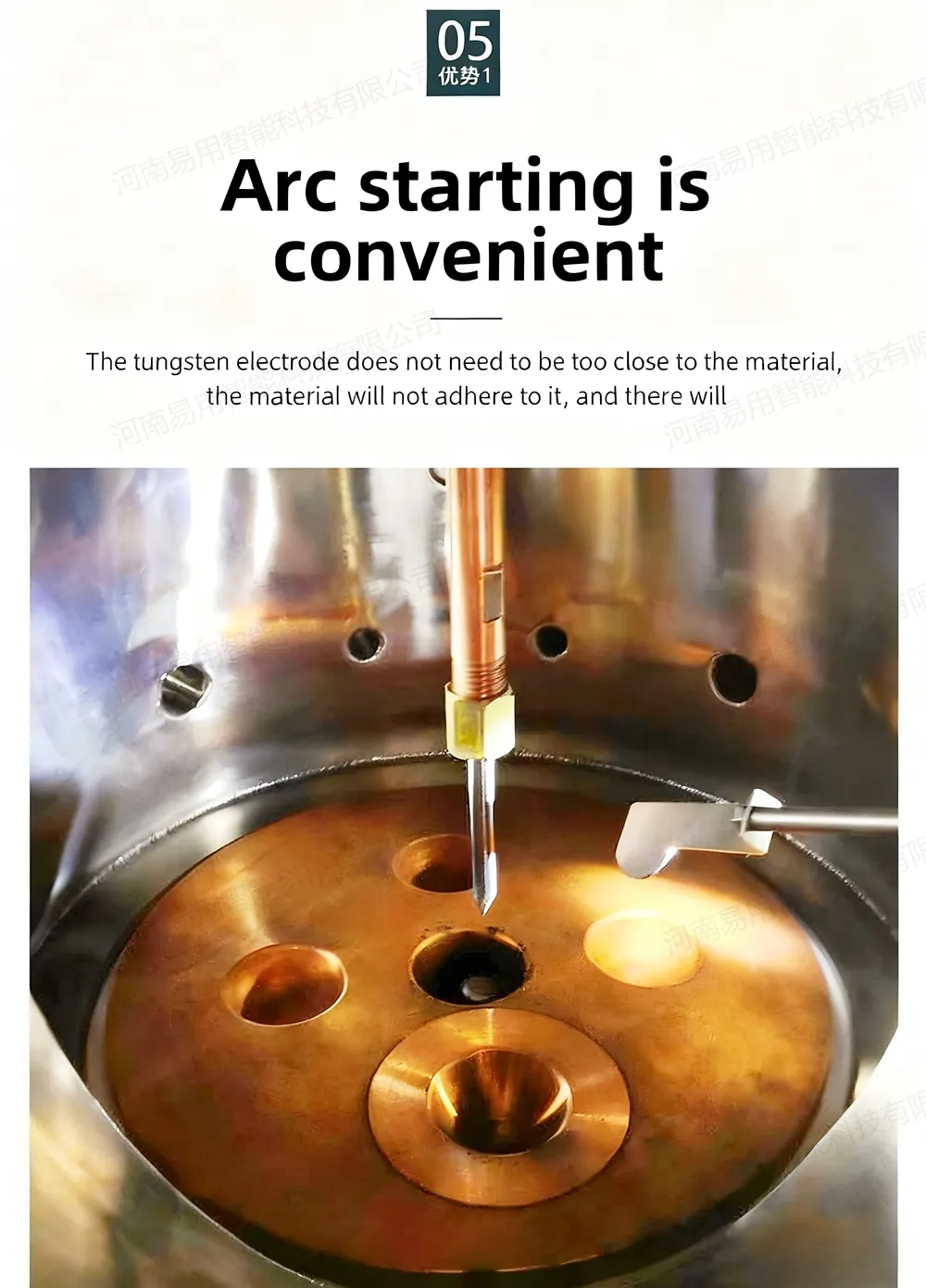

Arc melting is an electrothermal metallurgical process that uses electrical energy to generate an arc between electrodes, or between an electrode and the material being melted, to melt metals. The arc can be generated using either direct current (DC) or alternating current (AC). When using AC, a momentary zero voltage occurs between the two electrodes. In vacuum melting, the low gas density between the electrodes can easily cause the arc to extinguish, so DC power is generally used. It is primarily used to melt active and high-melting-point metals such as titanium, zirconium, molybdenum, tantalum, and niobium, as well as their alloys. It is also used to melt alloy steels such as heat-resistant steel, stainless steel, tool steel, and bearing steel. The resulting metal has reduced gas and volatile impurity levels, resulting in a more uniform crystal structure and improved metal properties, while the ingot generally exhibits less central porosity.

Product Overview

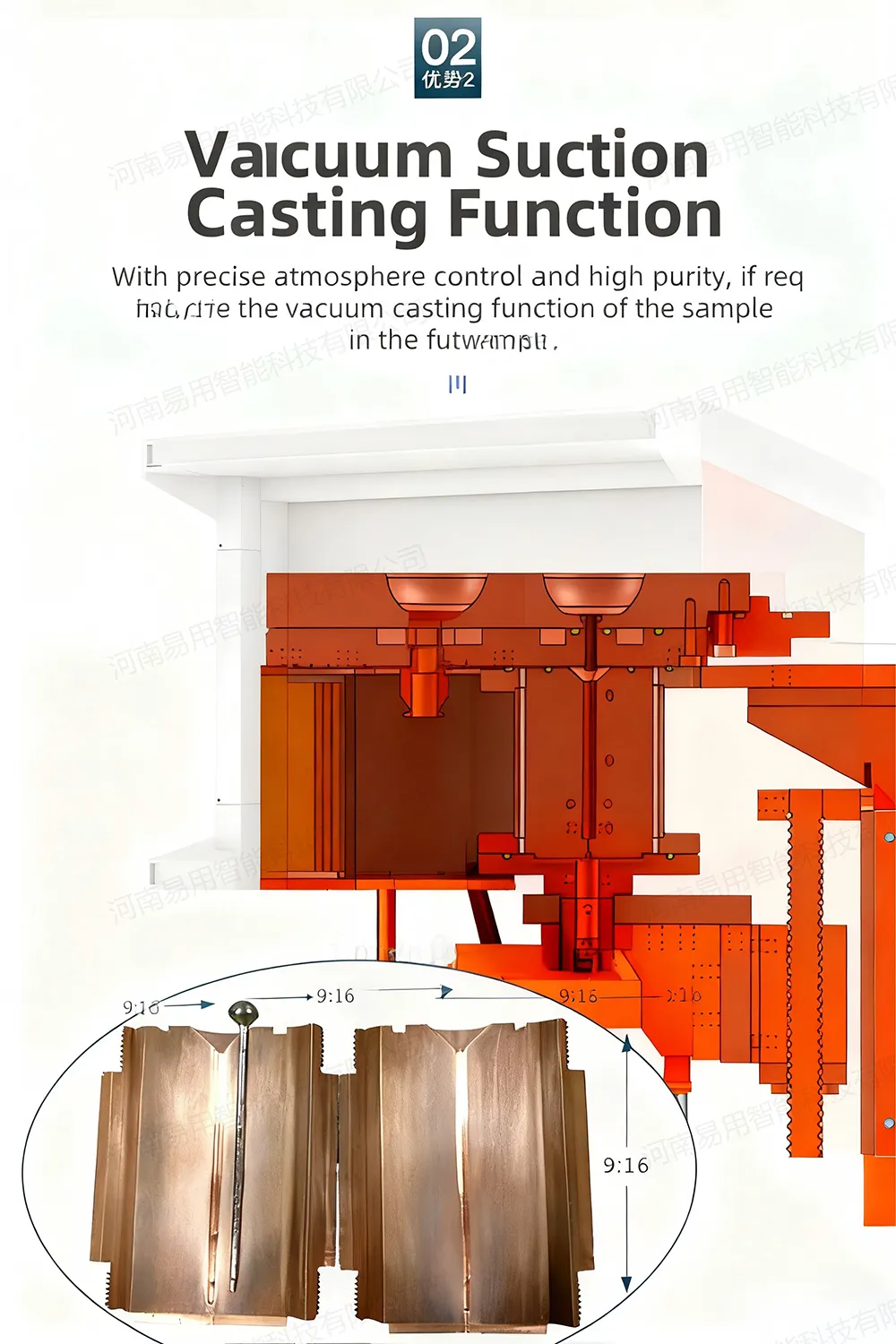

The system is a non-consumable furnace, mainly composed of an arc melting vacuum chamber, arc gun, arc melting power supply, water-cooled copper crucible, turning robot, electromagnetic stirring, gas system, vacuum system, vacuum measurement and electrical control system, installation cabinet, etc. It is equipped with a set of standard melting molds and a set of suction casting molds.

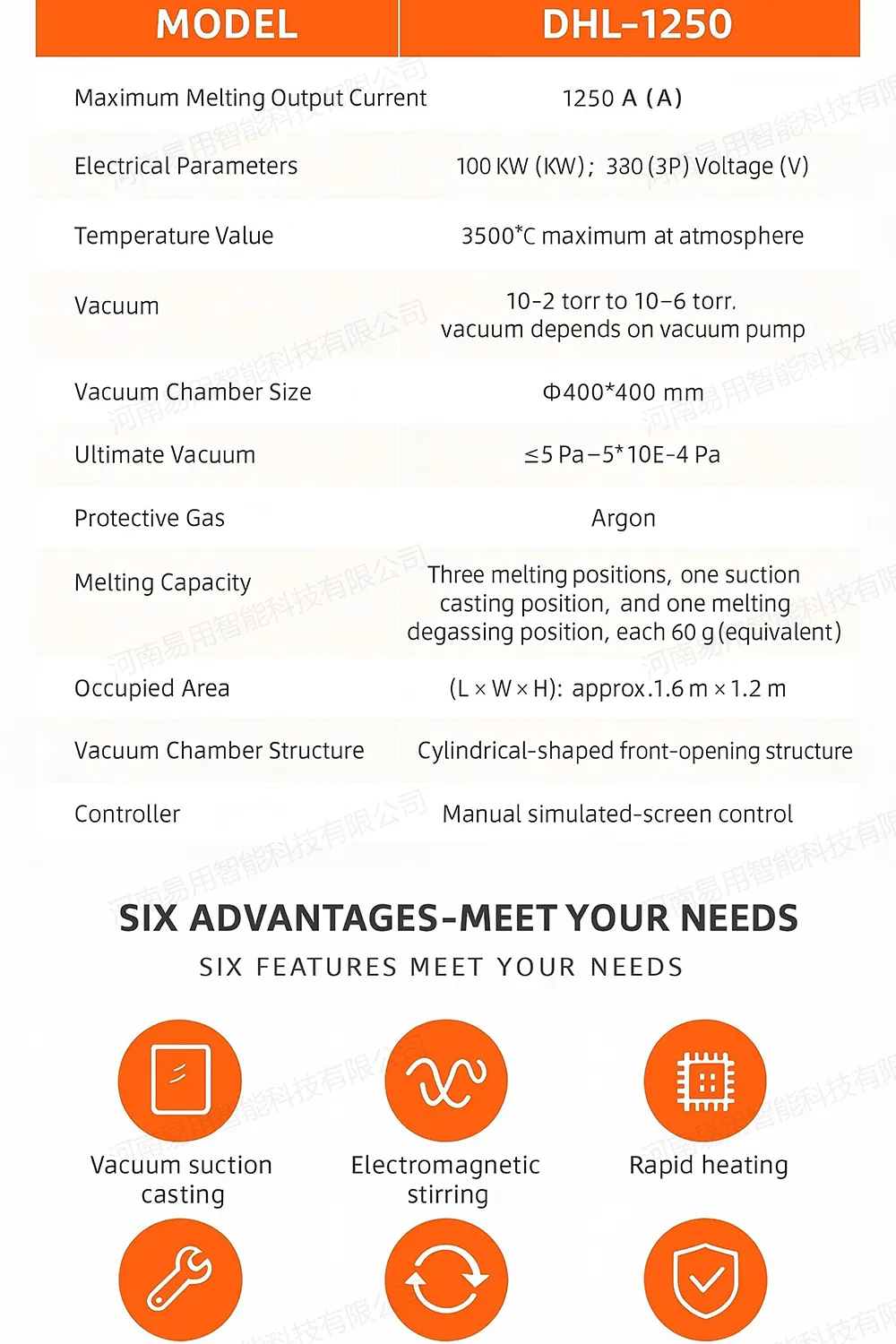

Vacuum arc melting furnace equipment parameters

1. Vacuum chamber structure: cylindrical front-opening structure

2. Vacuum chamber size: φ400X450mm

3. Ultimate vacuum degree: ≤5——5*10E-4Pa

4. Floor space (length x width x height): approximately 2 meters x 1.2 meters x 2.2 meters

5. Operation mode: Manual on the simulation screen

Featured Parameters

There are 5 standard stations (other stations can be customized), 1 alloy melting station 500 grams (in terms of iron) (with electromagnetic stirring), 2 alloy melting stations 200 grams (in terms of iron) (with electromagnetic stirring), 1 suction casting station 100 grams (in terms of iron), 1 melting and degassing station 100 grams (in terms of iron);

QR code

Contact information

15738867410

Online Message

Top