Precision casting with excellent quality

Integrated research and development, manufacturing, sales, and technical services of laboratory scientific instruments and intelligent equipment

National Consultation Hotline 15738867410

Integrated research and development, manufacturing, sales, and technical services of laboratory scientific instruments and intelligent equipment

National Consultation Hotline 15738867410

15738867410

Greenland Binhu International City (District 1), Erqi District, Zhengzhou City, Henan Province

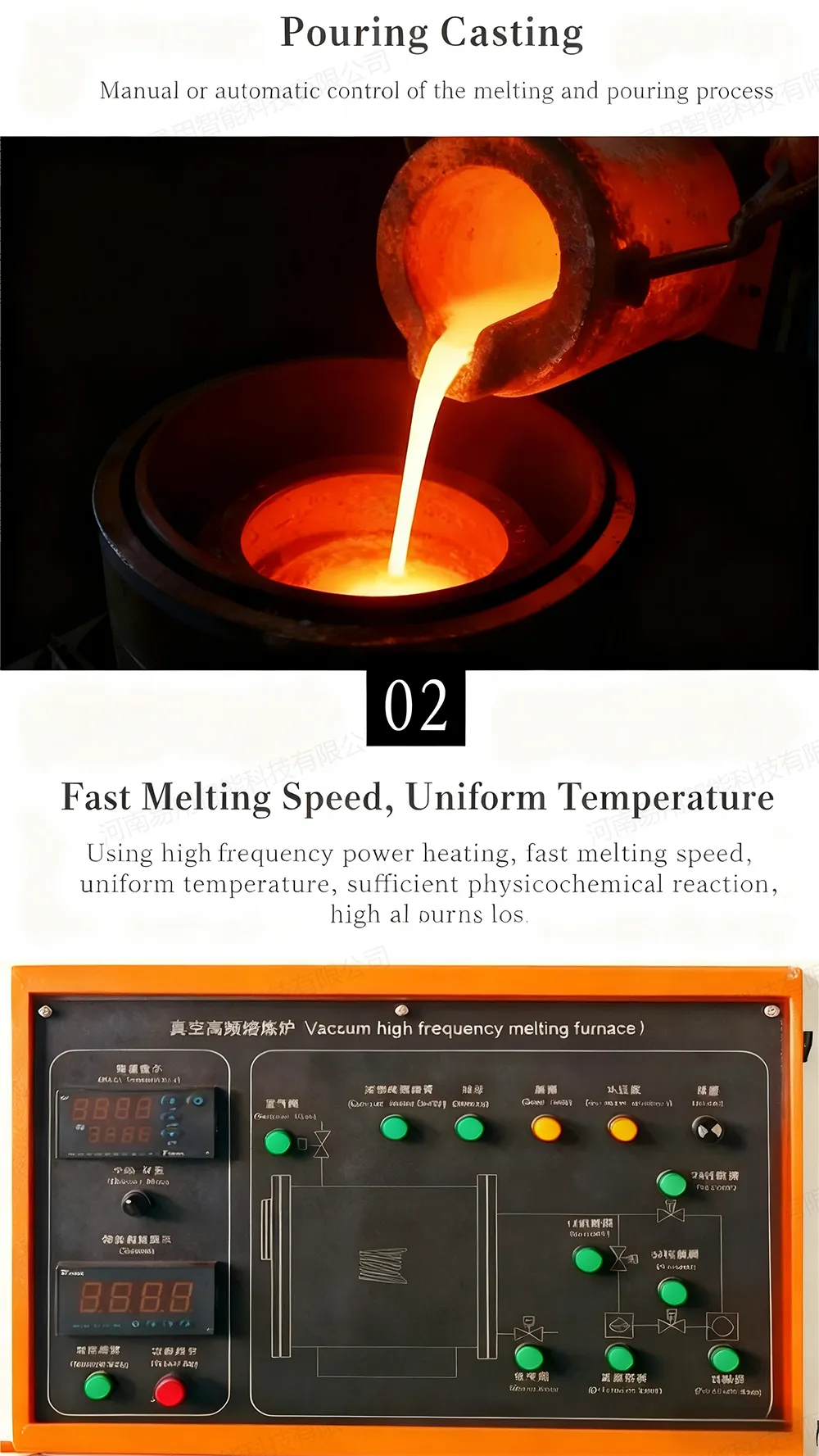

Details

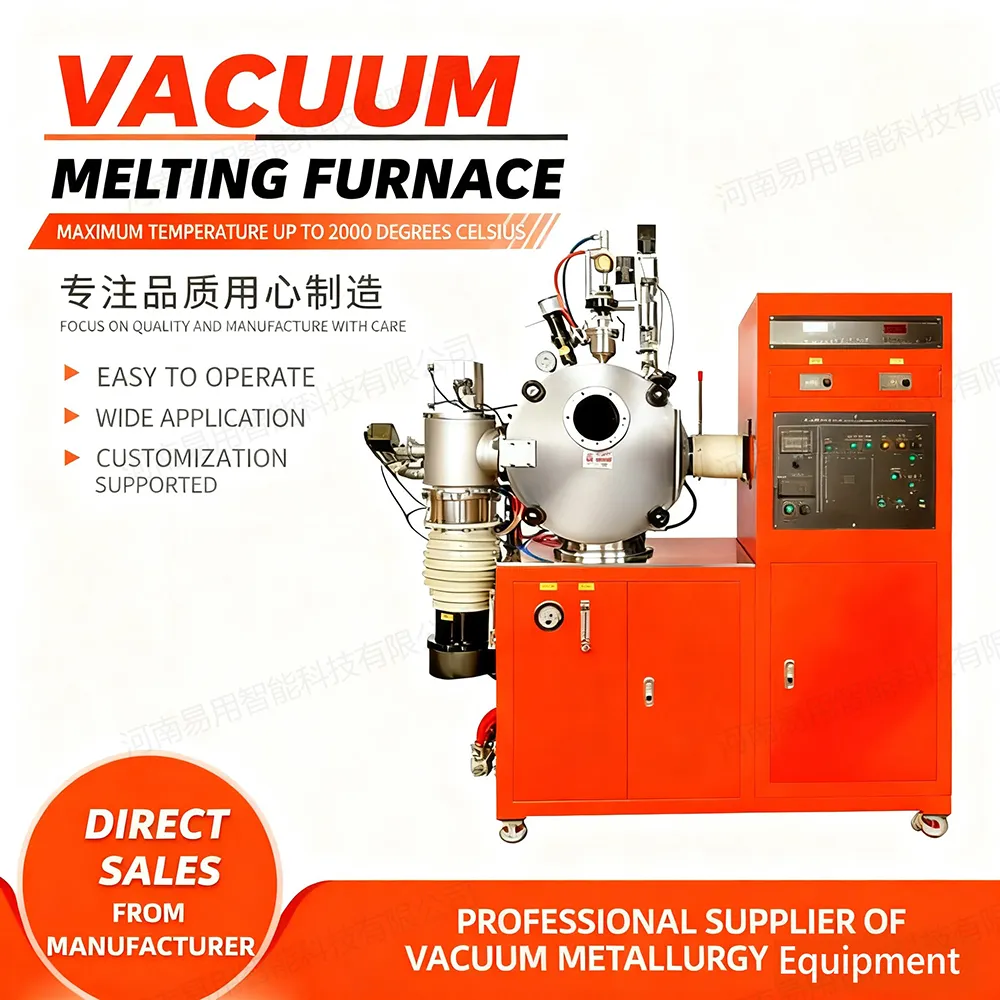

1Kg vacuum induction melting casting furnace vacuum nitriding furnace

Brief Description:

1Kg vacuum induction melting casting furnace vacuum nitriding furnace mainly uses induction heating of the metal in the graphite crucible under vacuum or protective atmosphere conditions. At the same time, materials can be added during the melting process to adjust the alloy components. After the metal is melted into liquid, it is rotated and stirred to obtain a finely mixed and fully molten alloy, which is then cast into a mold to finally prepare the alloy required for the experiment.

Detailed introduction :

1Kg Vacuum Induction Melting and Casting Furnace Vacuum Nitriding Furnace

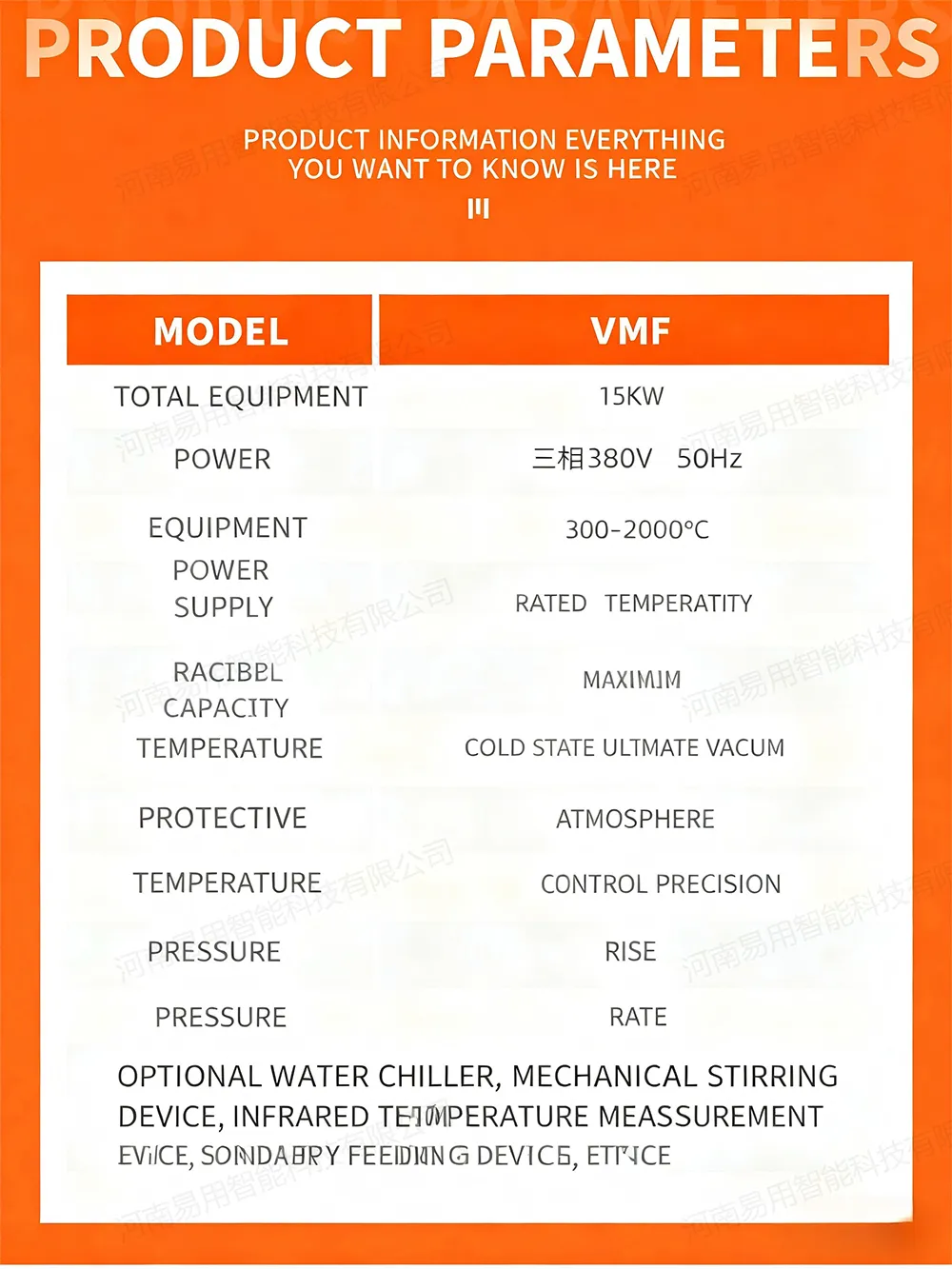

It is a streamlined high vacuum induction melting & casting furnace that can melt various alloys. The maximum melting capacity can reach 1kg (calculated according to Fe density) and the maximum melting temperature can reach 2000℃. It is equipped with a secondary charging mechanism that can perform secondary charging in a vacuum or atmosphere protection environment.

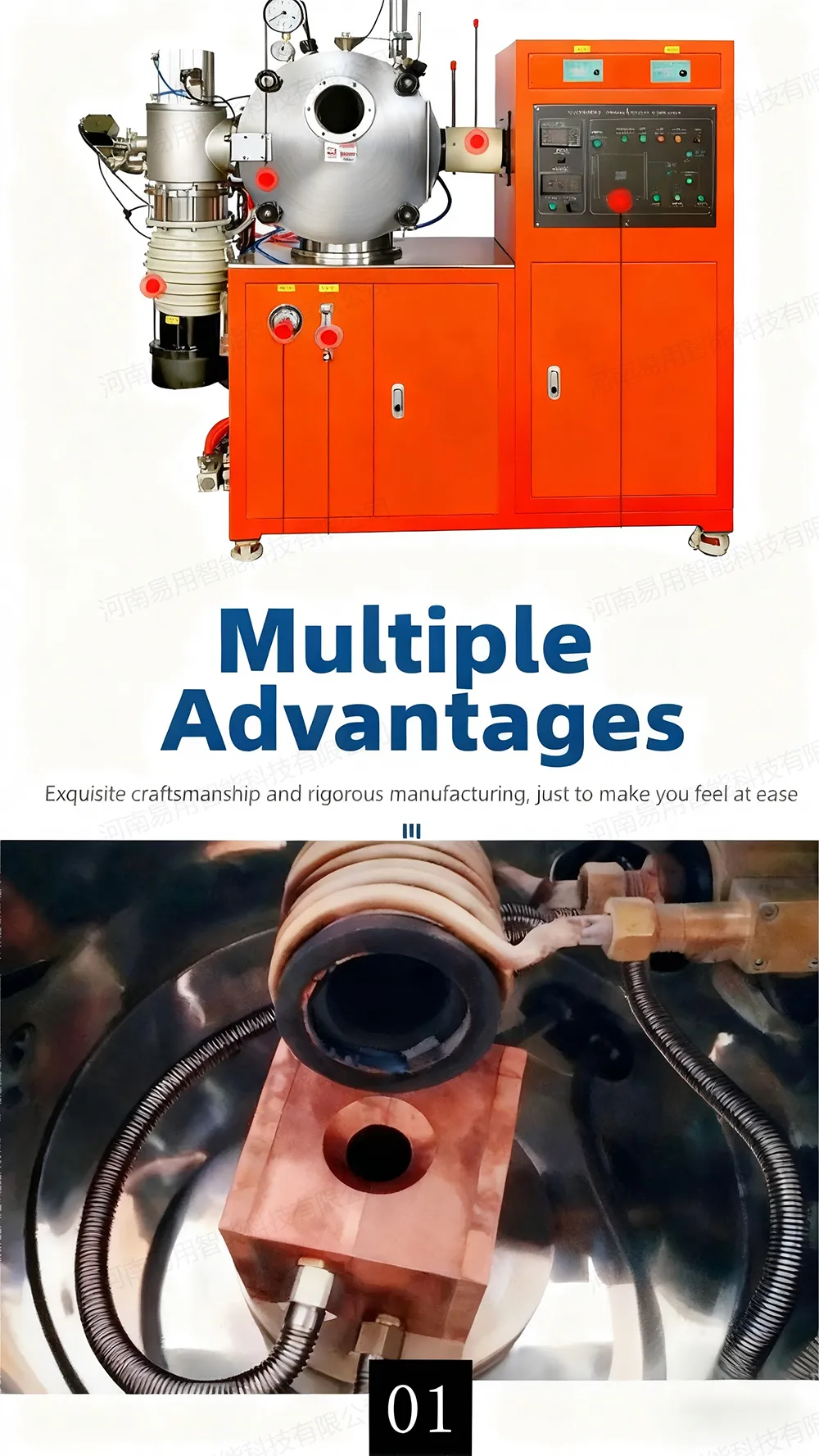

Equipped with a high-temperature stirring mechanism, it can stir the melted sample at high temperatures in a vacuum or atmospheric environment, ensuring more uniform melting. The vacuum level can reach 10-6 Torr (using a molecular pump system). Designed and manufactured specifically for industrial and research applications, it can perform the following processes on precious metals, high-purity, high-alloy steels, iron-, nickel-, and cobalt-based high-temperature resistant materials, non-ferrous metals, solar-grade silicon, specialty materials, and special/high-temperature alloys: melting, remelting and alloying, degassing and refining, homogenization, recycling, investment casting, precision casting, directional crystallization, and single crystal growth.

1Kg Vacuum Induction Melting and Casting Furnace Vacuum Nitriding Furnace Product Features

1. Reasonable layout, suitable for modular expansion or subsequent module supplement/upgrade;

2. Alloying, sampling or other melting operations in vacuum can be carried out through the vacuum sealing system;

3. Suitable for ingot casting, die casting and precision casting;

4. Convenient and safe control of process cycle;

5. The maximum melting temperature is greater than 2000 degrees;

6. Wide pressure range from 10-5Pa to 10Pa;

7. Manual or automatic control of melting and casting process (automatic pouring casting);

8. Effective volume 0.05 to 30 liters (50g-200kg);

9. Shorter vacuuming time and production cycle;

10. Increase process integrity and product quality through automatic casting control; reliability, durability, and easy maintenance

QR code

Contact information

15738867410

Online Message

Top