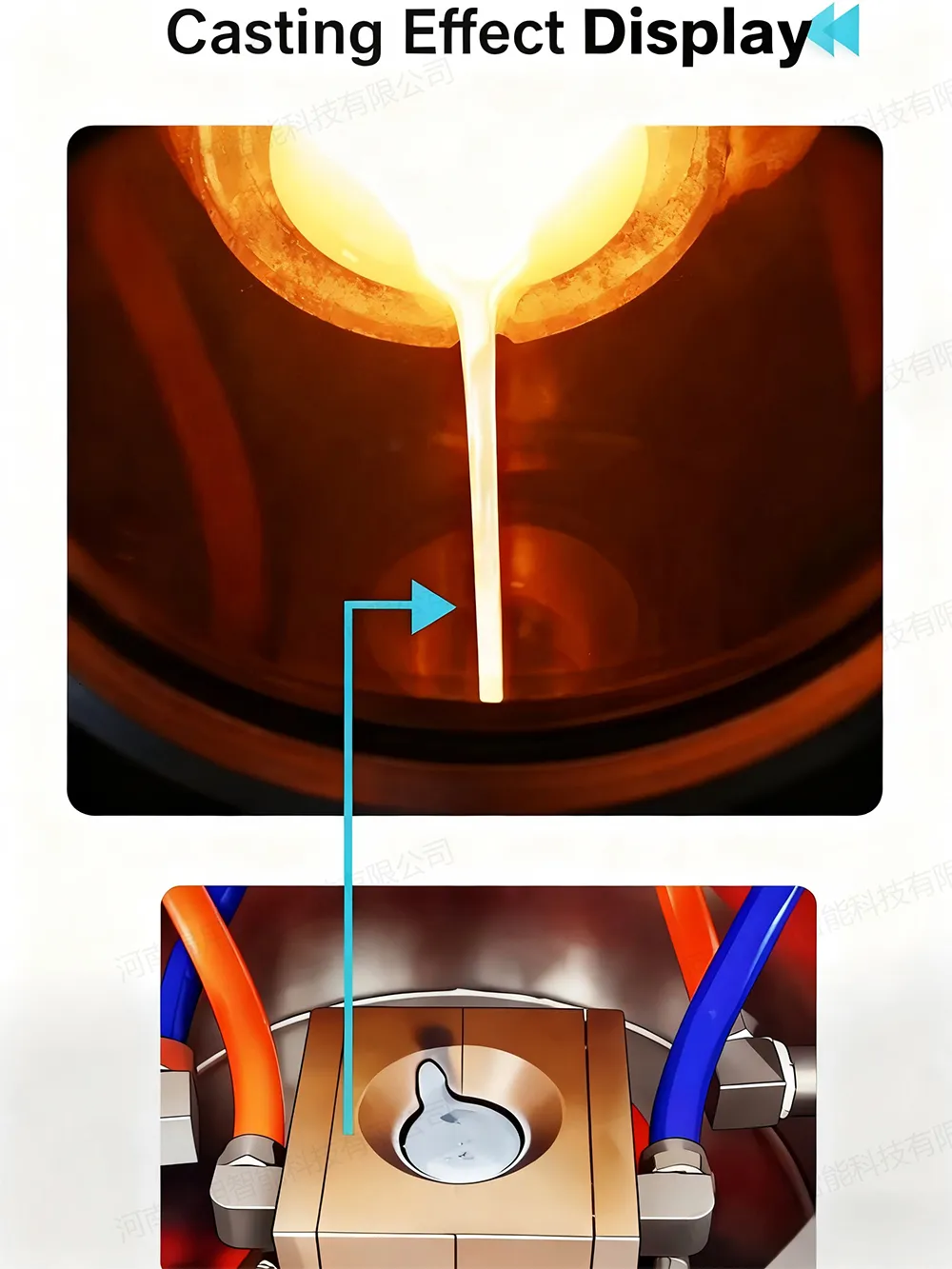

Precision casting with excellent quality

Integrated research and development, manufacturing, sales, and technical services of laboratory scientific instruments and intelligent equipment

National Consultation Hotline 15738867410

Integrated research and development, manufacturing, sales, and technical services of laboratory scientific instruments and intelligent equipment

National Consultation Hotline 15738867410

15738867410

Greenland Binhu International City (District 1), Erqi District, Zhengzhou City, Henan Province

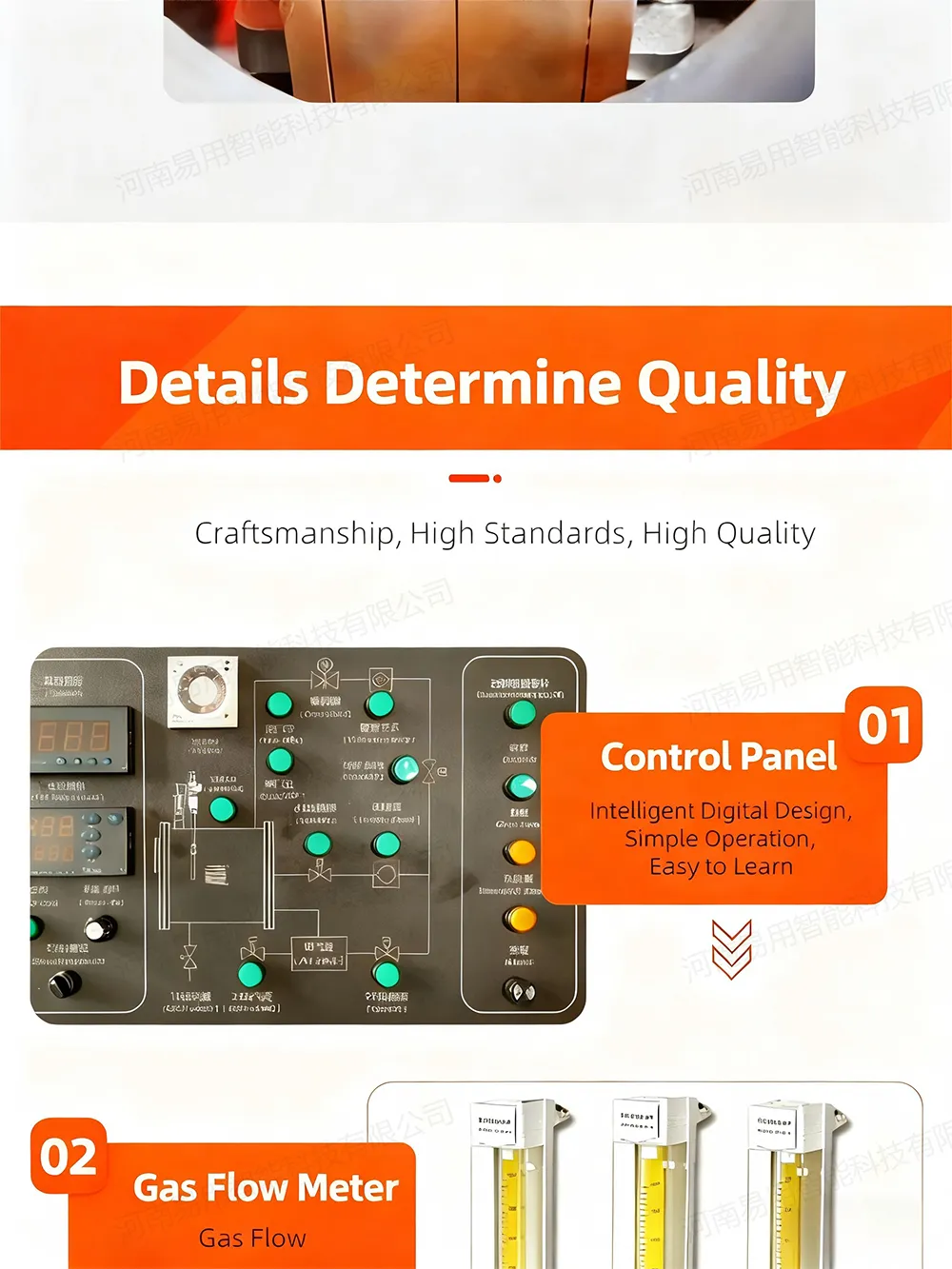

Details

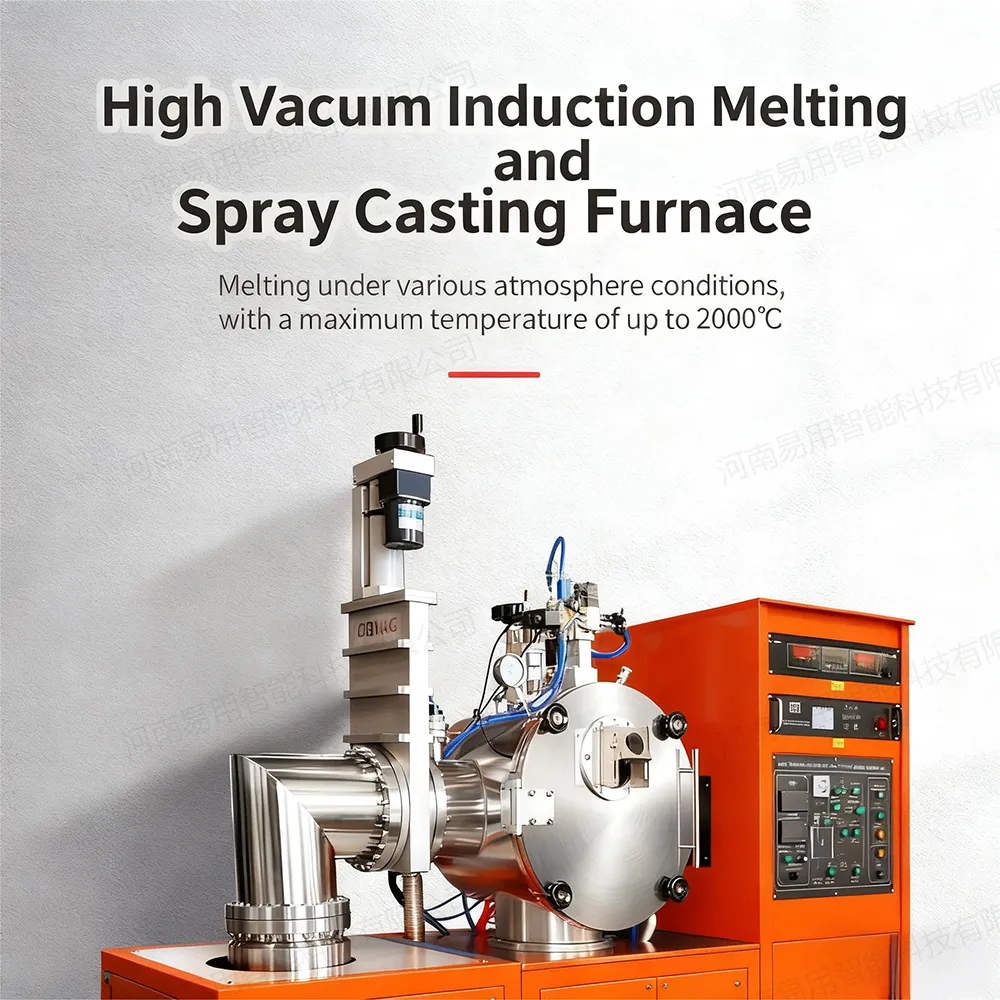

Vacuum induction flip casting and spray casting equipment

Brief Description:

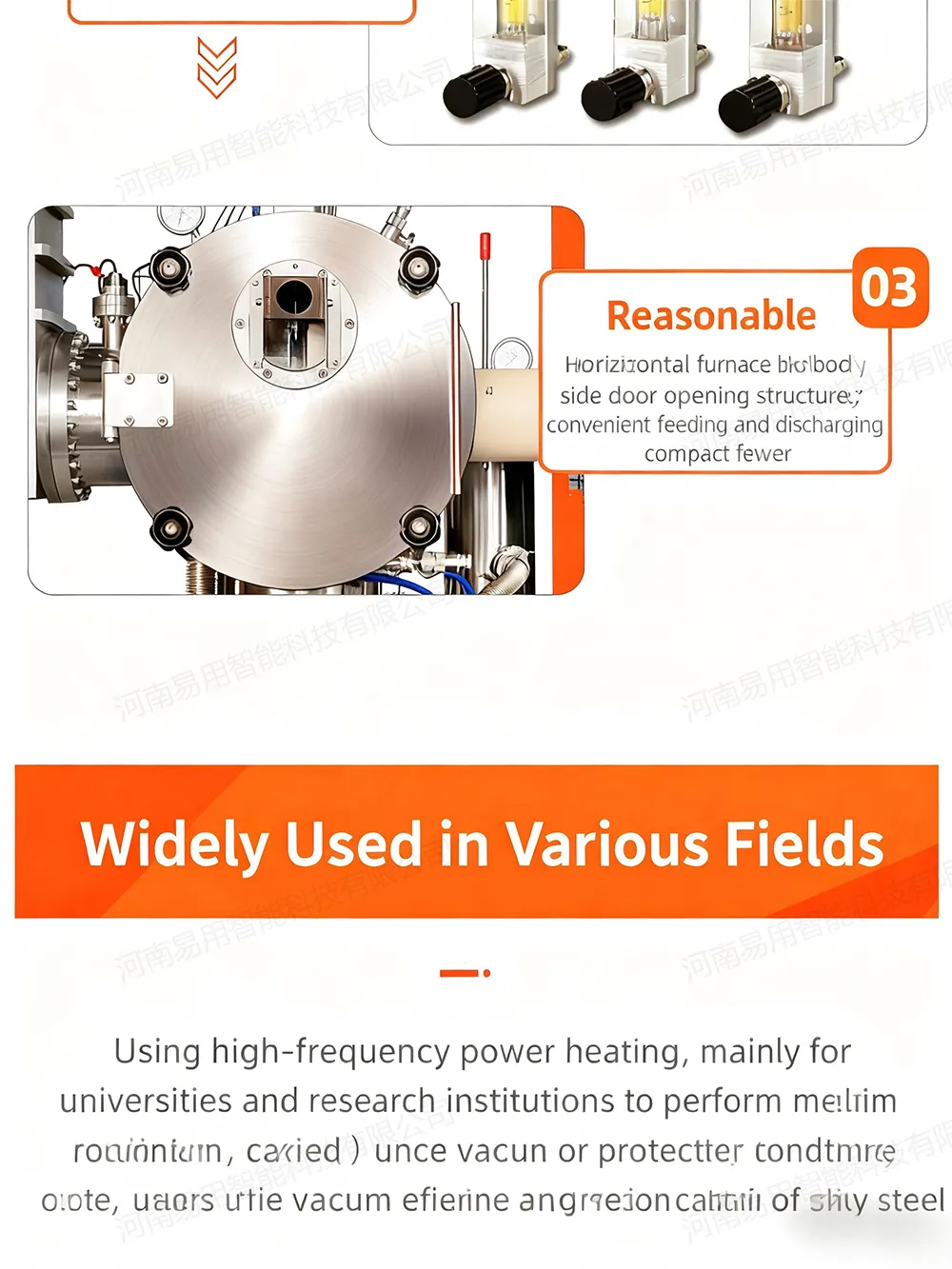

Vacuum induction flip casting and spray casting equipment is mainly used by colleges and universities, scientific research institutions and production enterprises to melt metal materials (such as stainless steel, nickel-based alloys, copper, alloy steel, nickel-cobalt alloys, rare earth neodymium iron boron, etc.) under vacuum or protective atmosphere conditions. It can also be used for vacuum refining and precision casting of alloy steel.

Detailed introduction:

Introduction to Vacuum Induction Tumble Casting and Spray Casting Equipment

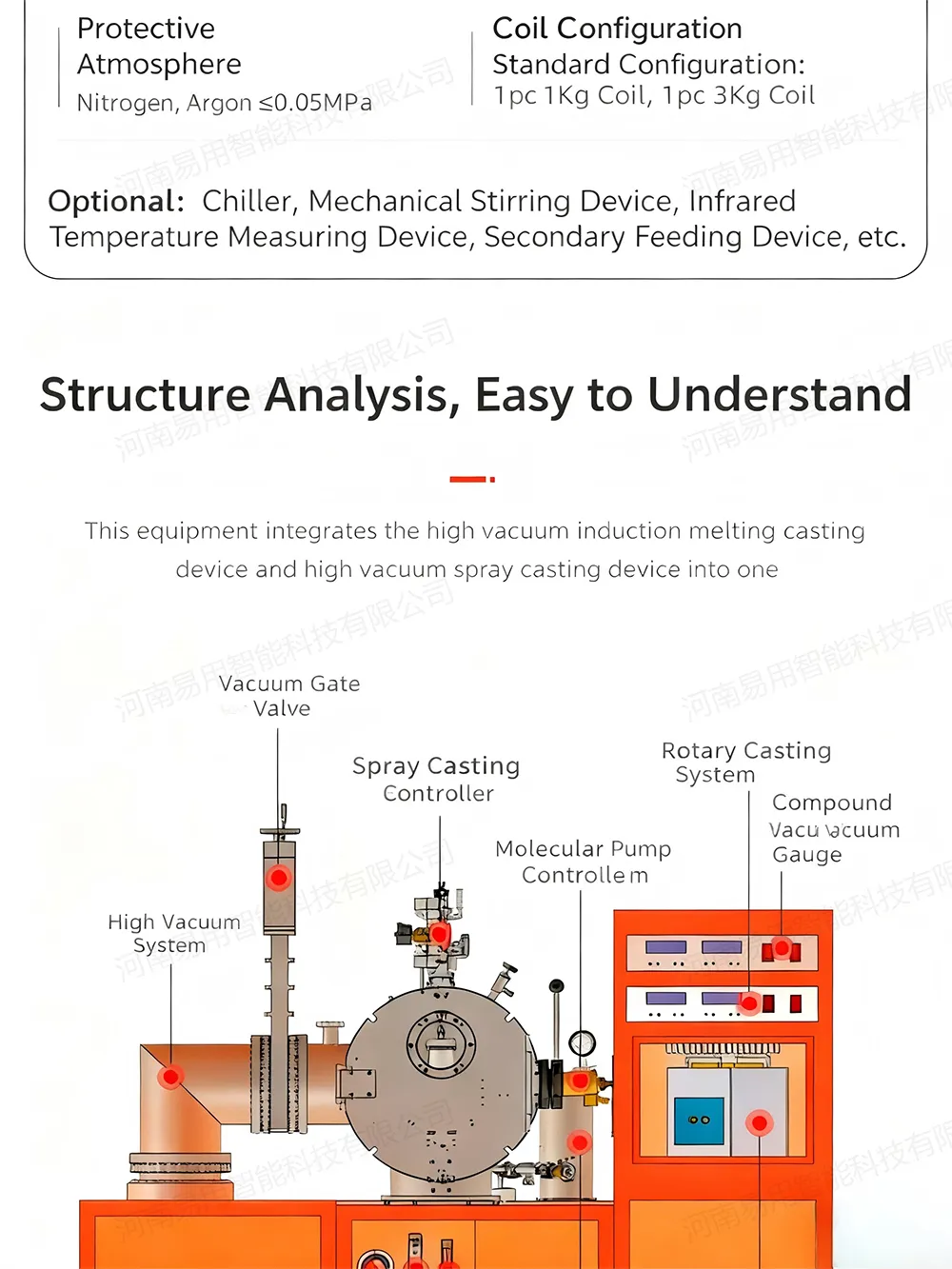

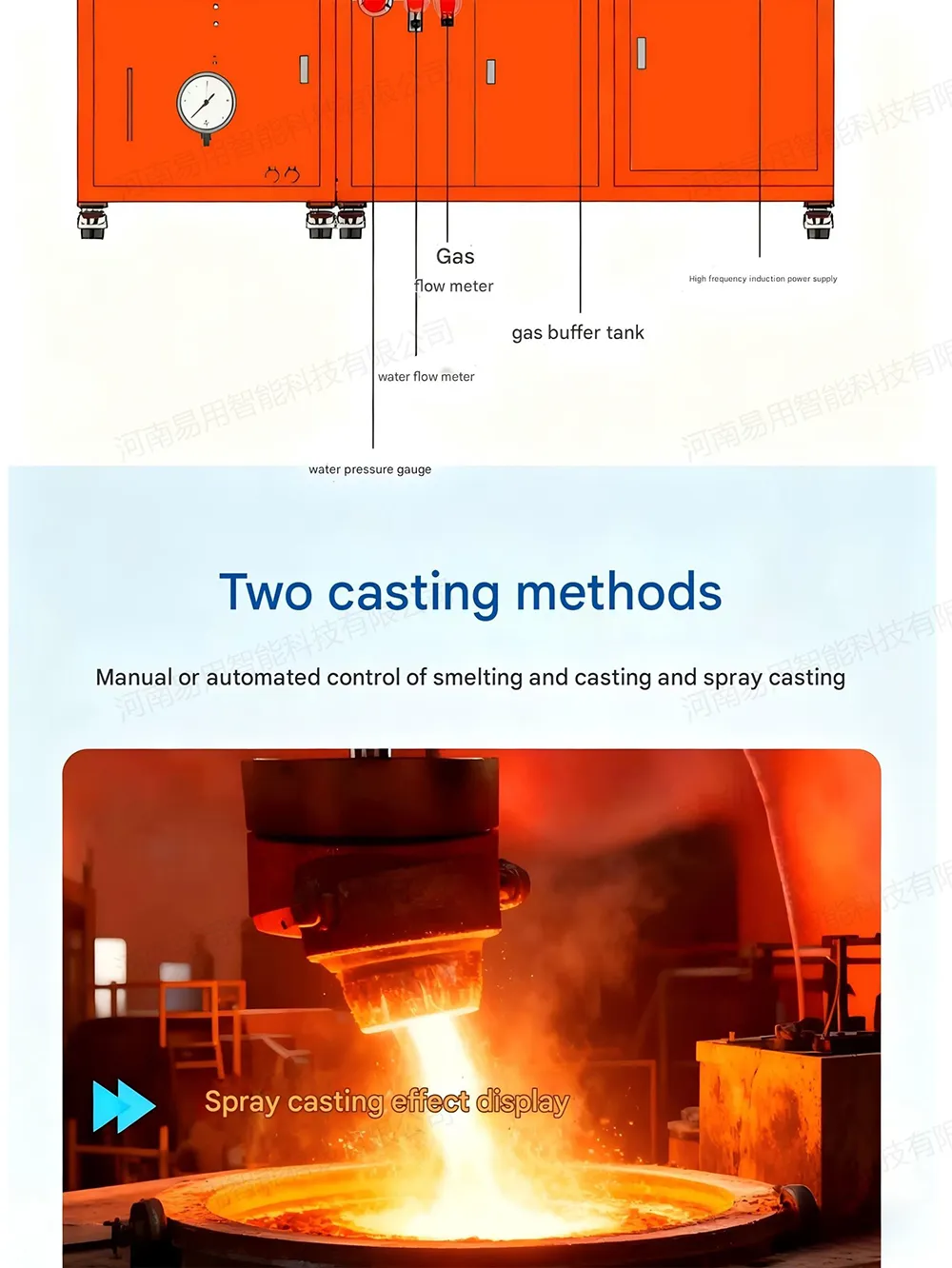

It integrates high vacuum induction melting and casting equipment and high vacuum spray casting equipment into one device, sharing a high vacuum system and a water cooling system. The equipment occupies a small area and is simple and convenient to operate.

The high vacuum induction melting and casting device and the high vacuum spray casting device share a vacuum chamber and adopt a circular furnace body with a side door structure, which is convenient for loading and unloading. The furnace body structure is compact and occupies a small space. It adopts high-frequency power heating. The high vacuum induction melting and casting device is mainly used for melting and casting metal materials (such as stainless steel, nickel-based alloys, copper, alloy steel, nickel-cobalt alloys, rare earth neodymium iron boron, etc.) under vacuum or protective atmosphere conditions. It can also prepare bulk metal amorphous materials and is suitable for research and experimental work on various amorphous and microcrystalline materials. It is widely used in the development and research of new rare earth permanent magnet materials, amorphous soft magnetic materials and nanomaterials science.

Main technical parameters of vacuum induction flip casting and spray casting equipment

1. Maximum melting amount of sample: 10~100g;

2. Vacuum degree: 5*10E-4Pa (shares vacuum system with high vacuum induction melting and casting device) pressure rise rate ≤1.67Pa/h, while starting to pump air from the atmosphere, it can reach 5*10-3Pa within 15-20min

3. Melting power: 15KW (frequency 30~80KHz) (shared with high vacuum induction melting and casting device)

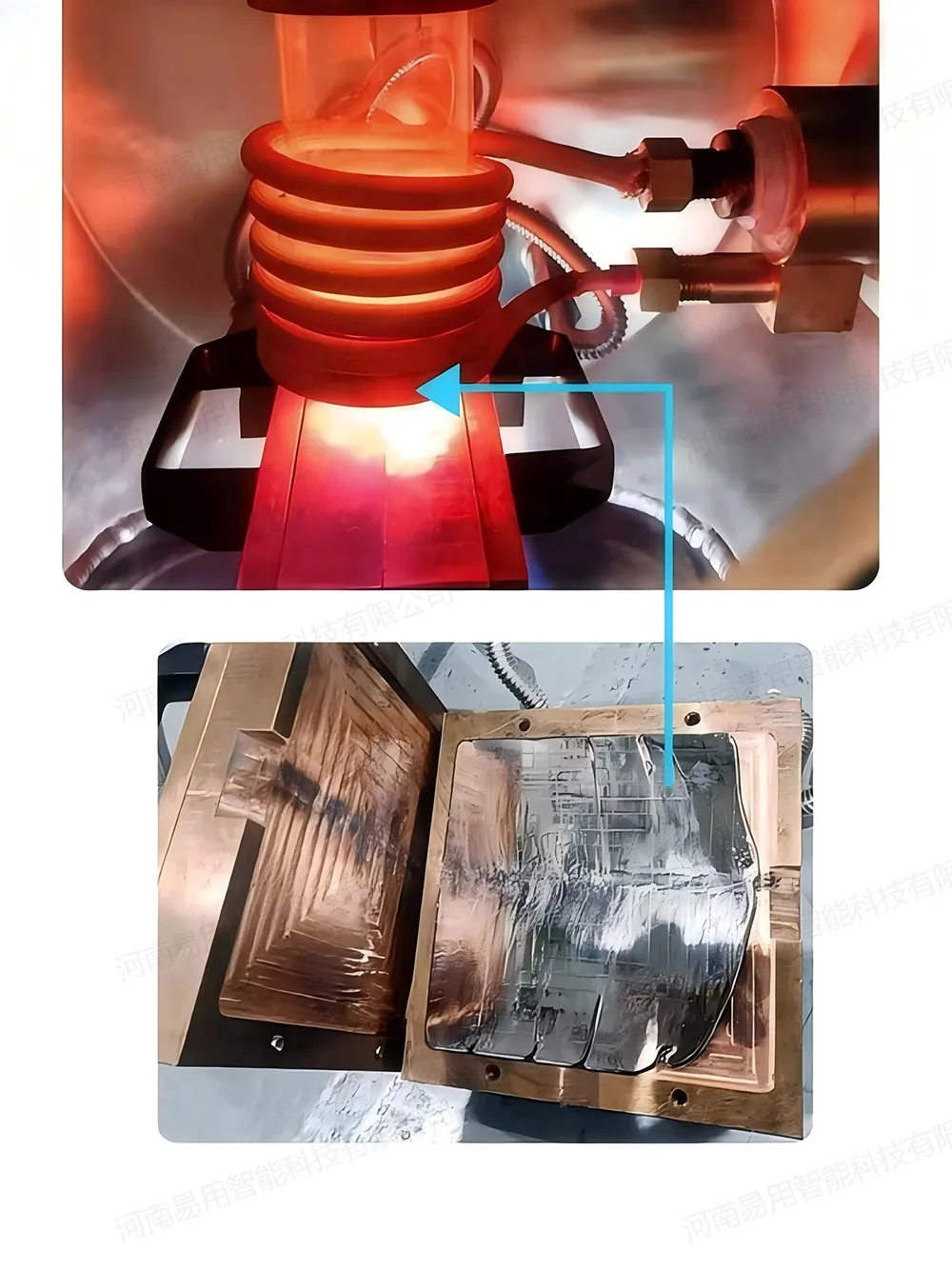

4. Melting crucible: Quartz (boron nitride crucible is optional) spray-cast quartz tube interface height is adjustable up and down, the induction coil melting capacity is 10-100g; dynamic seal adopts welded bellows structure.

5. Provide 1 set of standard water-cooled spray casting mold; the bottom of the mold is equipped with a lifting operating table, which can be fine-tuned up and down and left and right

6. Vacuum chamber size: D400 × 400mm ( D * L )

QR code

Contact information

15738867410

Online Message

Top