Precision casting with excellent quality

Integrated research and development, manufacturing, sales, and technical services of laboratory scientific instruments and intelligent equipment

National Consultation Hotline 15738867410

Integrated research and development, manufacturing, sales, and technical services of laboratory scientific instruments and intelligent equipment

National Consultation Hotline 15738867410

15738867410

Greenland Binhu International City (District 1), Erqi District, Zhengzhou City, Henan Province

Details

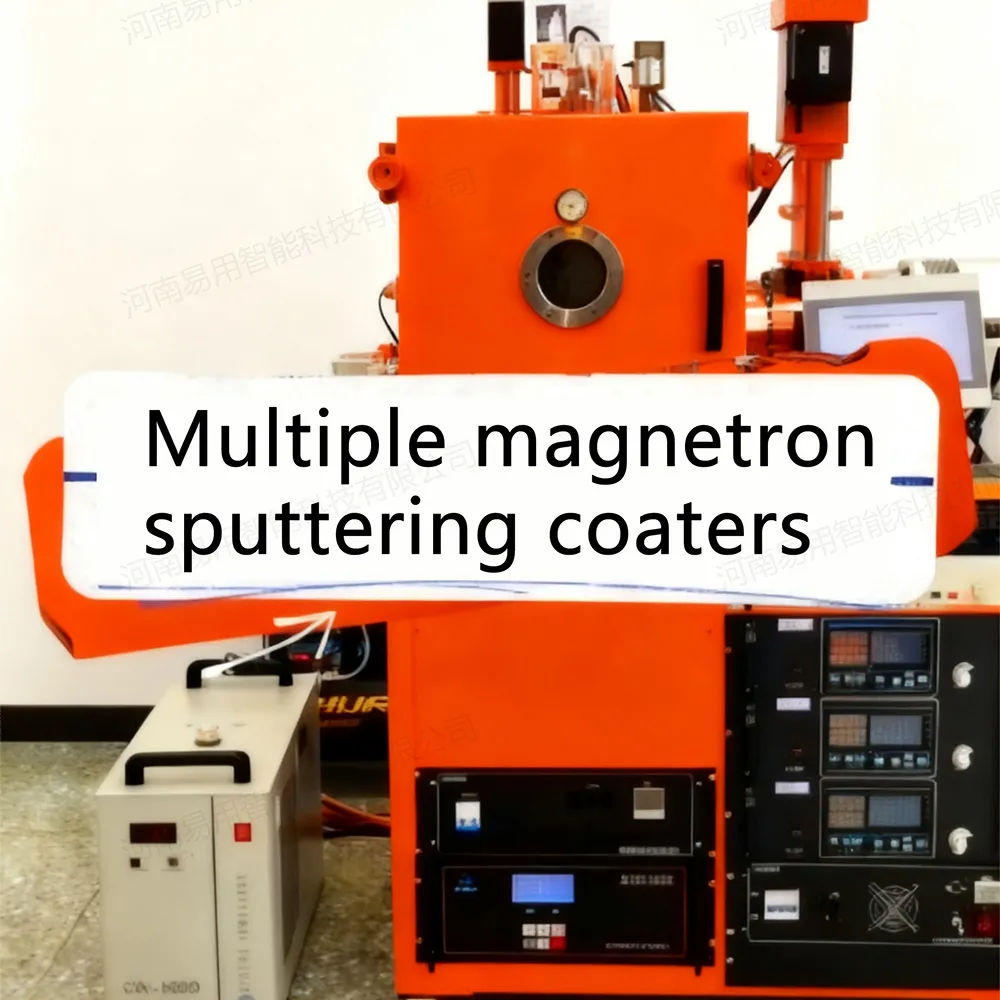

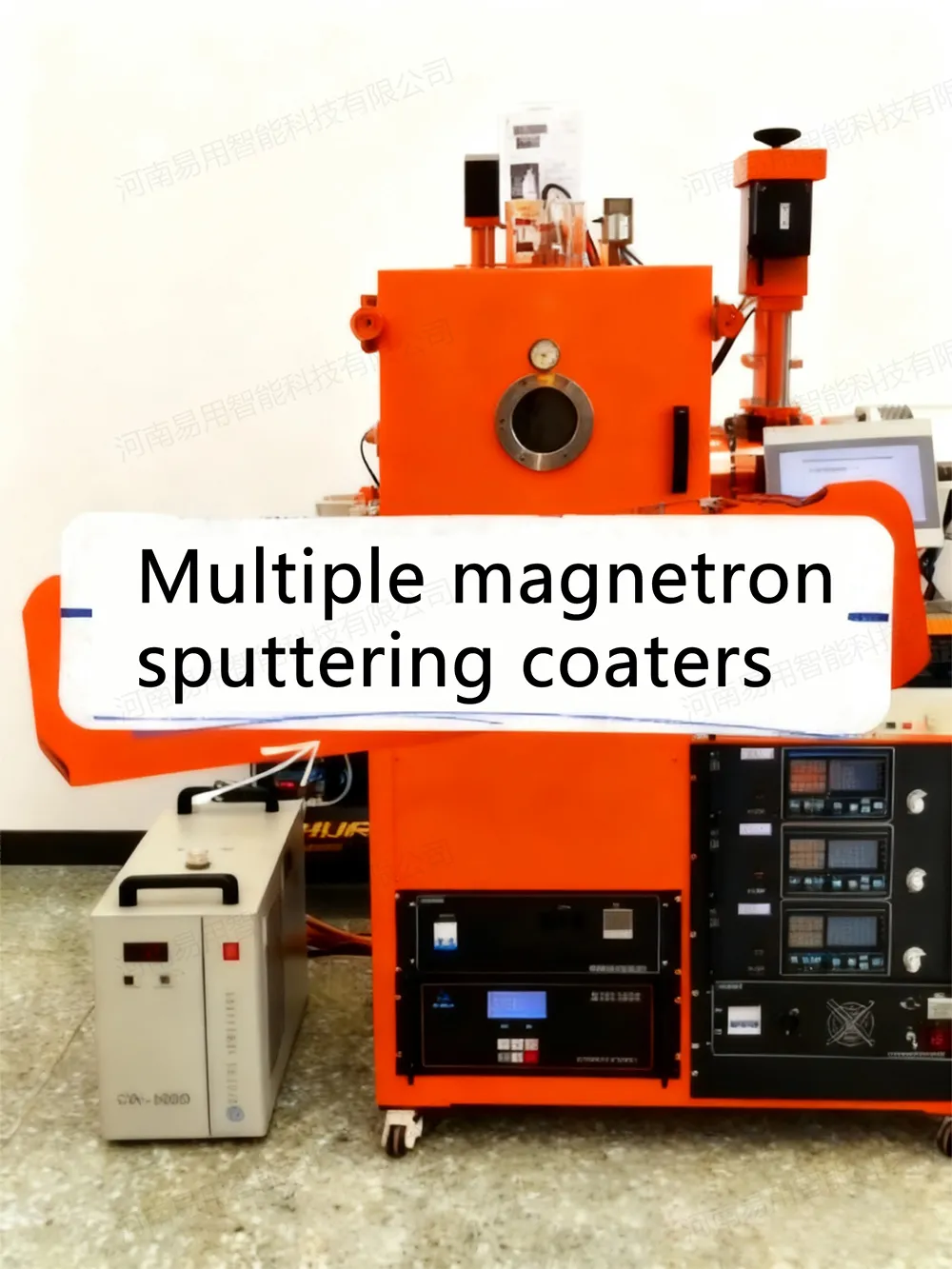

CK300 three-target magnetron sputtering coater

Equipment use:

It is used for the preparation of new thin film materials such as nano-scale single-layer and multi-layer functional films, hard films, metal films, semiconductor films, dielectric films, etc. It can be widely used in the research and small-batch preparation of thin film materials in colleges and universities, and research institutes. It is equipped with an anode layer ion source for cleaning and auxiliary deposition. At the same time, the equipment has a reverse sputtering cleaning function to improve the quality and firmness of the film.

Equipment composition

The system mainly consists of a sputtering vacuum chamber, permanent magnet magnetron sputtering targets (three targets), a single substrate heating platform, a DC power supply, a radio frequency power supply, a working gas circuit, an exhaust system, a vacuum measurement system, an electronic control system and an installation machine.

Technical indicators:

1. Adopt single-chamber D-type front-door structure, easy sample change and injection operation, stainless steel and vacuum materials ;

2. Ultimate vacuum: The ultimate vacuum of the sputtering chamber is ≤5×10-5Pa; the working vacuum can reach: 5×10-4Pa; Pressure rise rate: The vacuum is ≤10Pa after the pump is shut down for 12 hours; System leakage rate: 5×10-7PaL/S;

3. Magnetron targets and power supply: Three 3-inch magnetron targets, two of which are standard magnetic field magnetron targets and one is a high magnetic field magnetron target. The magnetron targets can be DC or RF; three RF power supplies, power 600W, 13.56MHz, automatic matching; the distance between the target and the sample is 40mm to 120mm ;

4. The sample has anti-sputtering function, which can be used to pre-clean the sample before plating ;

5. The equipment is equipped with an anode layer ion source, which can clean the sample and assist in the deposition of the sample during film coating ;

6. Process gas: 2 working gas lines: 2 independent mass flow controllers for reaction gas inlet and argon gas lines, using MKS mass flow meters; with gas mixing function; the gas pressure in the cavity can be measured, adjusted and controlled ;

7. Sputtering chamber baking lighting: adopt infrared heating degassing method, baking temperature: 150℃ ;

8. There is a lining plate in the vacuum chamber to prevent the sputtered material from directly sputtering onto the vacuum wall of the sputtering chamber ;

9. The equipment has the function of water and power off interlocking protection and the function of preventing misoperation.

QR code

Contact information

15738867410

Online Message

Top