Precision casting with excellent quality

Integrated research and development, manufacturing, sales, and technical services of laboratory scientific instruments and intelligent equipment

National Consultation Hotline 15738867410

Integrated research and development, manufacturing, sales, and technical services of laboratory scientific instruments and intelligent equipment

National Consultation Hotline 15738867410

15738867410

Greenland Binhu International City (District 1), Erqi District, Zhengzhou City, Henan Province

Details

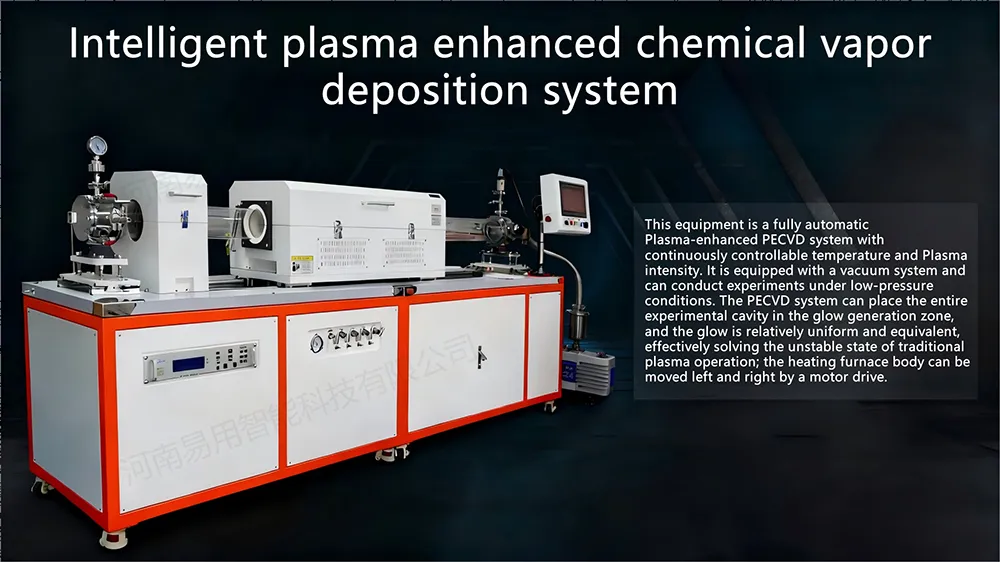

1200℃ Intelligent PECVD System

1. Equipment Introduction:

The Intelligent PECVD-500A-D is the latest model with all integrated control components. It can be equipped with a PE RF power supply, upgrading the CVD system to PECVD. When the reacting atmosphere enters the furnace tube, the RF power supply generates plasma, which promotes a more complete reaction. This plasma also acts as a reinforcement, significantly optimizing experimental process conditions. Our companys slide-type PECVD system ensures that the entire experimental chamber is within the glow generation zone, creating a uniform and equal glow. This technology effectively resolves the instability of traditional plasma operation. The resulting ionization range and intensity are a hundred times greater than those of traditional PECVD, eliminating uneven material accumulation. Compared to traditional CVD systems, the growth temperature is lower. The slide-type furnace achieves rapid heating and cooling, and the equipments unique patented technology ensures a uniform and equal glow throughout the tube, ensuring consistent growth.

2. Product Features:

1. High film deposition rate: RF glow technology greatly improves the deposition rate of thin films, which can reach 10Å/S.

2. High uniformity over large areas: Using advanced multi-point RF feeding technology, special gas path distribution and heating technology, the film uniformity index reaches 8%.

3. High consistency: Using advanced design concepts in the semiconductor industry, the deviation between each substrate deposited in one go is less than 2%.

4. High process stability: Highly stable equipment ensures the continuity and stability of the process.

3. Product parameters:

Single temperature zone heating system | |

Input power | Single phase, 220V 50Hz |

Rated power | 3KW |

Maximum temperature | 1200℃ |

Operating temperature | ≤1100℃ |

Temperature control method | 30-segment programmable temperature control, PID parameter self-tuning, built-in PLC control program The temperature control system and the sliding (time and distance) of the slide rail furnace can be set to program control |

Heating zone length | 440mm |

Length of constant temperature zone | 200mm |

Temperature control accuracy | ±1℃ |

Effective size of furnace | Ф60*1650mm |

Heating element | Resistance wire (molybdenum-doped iron-chromium-aluminum alloy) |

Thermocouple | K-type thermocouple |

Furnace material | Alumina, high temperature fiber products |

PE RF power supply | |

This CVD system can be equipped with a PE RF power supply, upgrading the CVD system to PECVD. When the reacting atmosphere enters the furnace tube, the RF power generates ions, which promote a more complete reaction. The plasma also acts as a booster, significantly optimizing experimental process conditions. | |

Signal frequency | 13.56MHz±0.005% |

Power output range | 500W |

RF output interface | 50 Ω, N-type, female |

Power stability | ±0.1% |

Harmonic components | ≤-50dbc |

Supply voltage | Single-phase AC (187V-253V) frequency 50/60HZ |

Overall efficiency | ≥70% |

Power Factor | ≥90% |

Cooling method | Forced air cooling |

Five-way proton flow control system | |

The gas supply system can control the mixing ratio of 4 gases at different flow rates. A gas scrubber can also be installed according to experimental requirements. The mass flow meter is installed in a sealed movable cabinet and is composed of ultra-clean double-polished stainless steel pipes connected with precision double-ferrule connectors, and is controlled by a touch screen. | |

Connector Type | Double ferrule stainless steel connector |

Standard range (N 2 ) | Argon: 1000 sccm, Hydrogen: 300 sccm, Methane: 100 sccm, Nitrogen: 500 sccm, Oxygen: 100 sccm |

Accuracy | ±1.5% |

Linear | ±0.5~1.5% |

Repeatability | ±0.2% |

Response time | Gas characteristics: 1~4 Sec, Electrical characteristics: 10 Sec |

Working pressure difference range | 0.1~0.5 MPa |

Maximum pressure | 3MPa |

interface | Φ6 or 1/4 optional |

show | 4-digit display |

Working environment temperature | 5~45 high purity gas |

Pressure vacuum gauge | -0.1~0.15 MPa, 0.01 MPa/grid |

Vacuum unit | |

The vacuum unit is equipped with a bipolar rotary vane mechanical pump, a capacitance vacuum gauge, and supporting bellows, a manual flapper valve, clamps, and other connecting components. The equipments cold-state ultimate vacuum can reach 0.5 Pa. | |

Operating voltage | 220V±10% 50~60HZ |

power | 1KW |

Pumping rate | 16m³/h |

Ultimate vacuum | 0.5Pa |

Air intake diameter | KF25 |

Exhaust port diameter | KF25 |

Connection method | Use bellows, the manual flapper valve is connected to the bellows |

Capacitance vacuum gauge | ZDM-I (with communication) can communicate with touch screen |

Vacuum gauge measurement range optional 5-5000Pa | |

No coefficient conversion is required due to different types of measured gases | |

High accuracy and repeatability, short response time | |

Pressure control system | |

Main components | Butterfly valve, pressure controller, capacitance vacuum gauge |

effect | According to the experimental requirements, add a butterfly valve (regulating valve) and a vacuum gauge between the outlet and the pump. |

The vacuum gauge can detect the pressure in the pipe and adjust the opening size of the butterfly valve (regulating valve) through the PLC | |

To achieve constant pressure in the control tube | |

Pressure range | 100~100000Pa |

Control accuracy | ±5% of measured value |

QR code

Contact information

15738867410

Online Message

Top