Precision casting with excellent quality

Integrated research and development, manufacturing, sales, and technical services of laboratory scientific instruments and intelligent equipment

National Consultation Hotline 15738867410

Integrated research and development, manufacturing, sales, and technical services of laboratory scientific instruments and intelligent equipment

National Consultation Hotline 15738867410

15738867410

Greenland Binhu International City (District 1), Erqi District, Zhengzhou City, Henan Province

Details

Small roller coating machine

Product Description

This equipment features a precision roller system design, compact structure, and easy operation. It is designed for colleges, universities, research institutions, and small R&D laboratories. The core function of the equipment is to achieve uniform coating of various substrates through roller coating technology at room temperature or controlled temperature environment. The materials that can be processed include:

Polymer materials (such as polyimide, PET, PVC, etc.);

Metal foil (such as copper foil, aluminum foil, stainless steel foil, etc.);

Composite materials (such as carbon fiber cloth, nanofiber membrane, etc.).

The equipment is suitable for preparing a variety of functional coatings, such as:

Electronic information field : flexible circuit board insulation layer, OLED substrate packaging coating, sensor base coating;

New energy field : lithium battery electrode coating (positive and negative electrode slurry), solid-state battery electrolyte coating, fuel cell proton exchange membrane;

Optical field : anti-glare coating for optical lenses, AR anti-reflection coating, flexible display touch coating;

Biomedical field : antibacterial coatings for medical catheters, biochip substrate coatings, and transdermal drug delivery patch coatings .

Features

1. High-precision coating performance

Optimized roller system design : Using a combination of chrome-plated steel rollers or silicone rollers, the coating thickness can be controlled in the range of 5-200μm, with a uniformity error of ≤±2%, supporting the preparation of nano-level ultra-thin coatings.

Multi-mode coating : supports multiple modes such as forward coating , reverse coating , and comma roller coating , and is suitable for materials with different viscosities such as solutions, slurries, and emulsions (viscosity range 1-10000cP).

2. Intelligent process control

Full process automation : Equipped with a PLC control system, it supports custom coating parameters (such as roller speed, coating gap, slurry supply rate, etc.), and can preset more than 15 sets of process programs. After one-click start, it automatically completes the processes of substrate transportation, coating , and drying (optional).

Precision temperature control system : The coating roller can be equipped with an optional heating/cooling module (temperature range: room temperature - 150°C, accuracy ±1°C), suitable for coating temperature-sensitive materials (such as hot melt adhesives and thermosetting resins).

3. Flexible environment adaptation

Wide-format substrate compatibility : Standard coating width is 300mm, with an optional 500mm wide-format model available, supporting coating on rolls (roll diameter ≤ 300mm) or sheets (maximum size 500mm×500mm) .

Multi-scenario scalability : Can be integrated into cleanrooms (supporting ISO Class 5 cleanliness) or configured with local purification modules to meet high-cleanliness coating requirements (such as in the microelectronics and medical fields).

4. Humanized design and safety assurance

Visual operation interface : equipped with a 7-inch color touch screen, which displays parameters such as roller speed, coating thickness, temperature, slurry remaining amount in real time, and supports historical data export (USB interface).

Safety protection mechanism : equipped with roller overload protection, emergency stop button, slurry leakage monitoring alarm and other functions to ensure the safety of operators.

Easy maintenance : The roller system adopts a quick-detachable structure. Cleaning and replacing the roller can be completed within 15 minutes. The automatic cleaning module (optional) can further improve efficiency.

5. Scalability and compatibility

Optional upgrade modules :

Online detection components : Beta-ray thickness gauge and laser roughness meter can be installed to monitor coating thickness and surface flatness in real time;

Drying and curing system : integrated infrared drying oven (temperature range: room temperature - 200°C) or UV curing module to achieve coating -drying integration;

Automatic rewinding and unwinding device : supports automatic coil tension control (tension range 5-50N), suitable for continuous coating process.

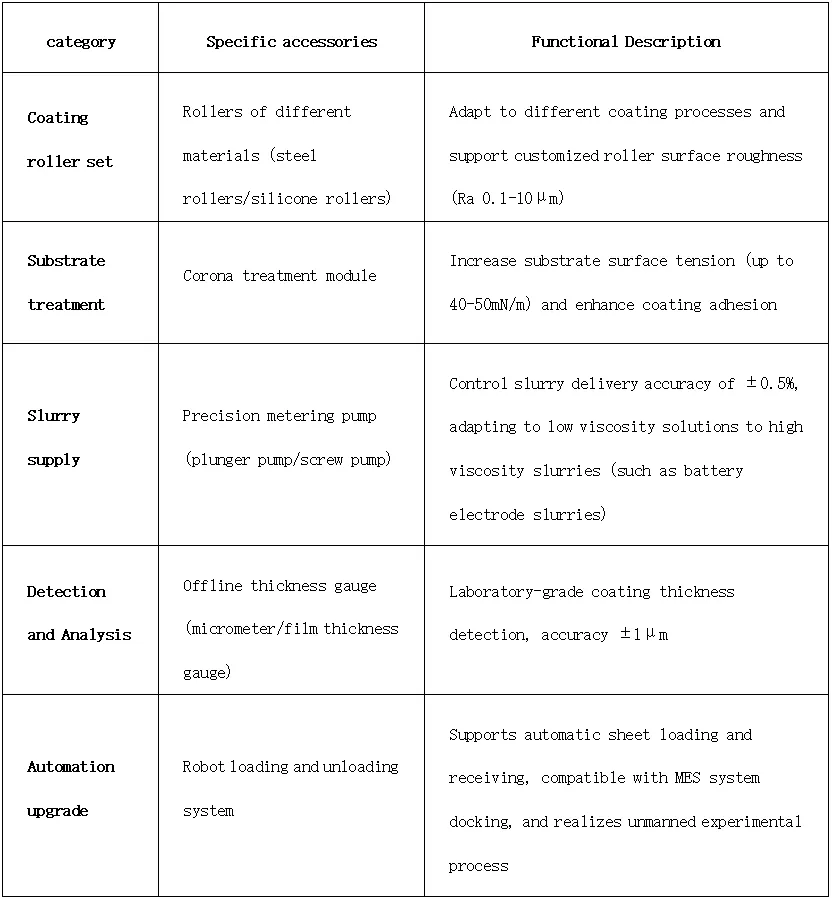

Optional accessories

Typical application scenarios

1.Lithium battery R&D : coating lithium iron phosphate (LFP)/ternary material slurry on copper foil/aluminum foil to prepare electrode plates;

2.Flexible electronics : coating silver nanowire conductive paste on PET substrate to prepare flexible touch screen electrodes;

3.Optical thin films : Applying a silicon dioxide (SiO₂) nano-coating on a glass substrate to prepare an anti-fingerprint film;

4.Biochip : Protein solution is evenly coated on a glass slide for chip microarray preparation.

Summary of equipment advantages

One machine with multiple functions : compatible with various processes such as film coating , coating, and laminating, meeting the needs of all stages from laboratory trials to pilot-scale scale-up;

Precise and controllable : The control accuracy of key parameters (thickness, temperature, speed) reaches the industry-leading level, and the experimental repeatability error is less than 3%;

High efficiency and low consumption : It uses energy-saving servo motors, which reduce energy consumption by 15% compared to traditional equipment and support 24-hour continuous operation.

QR code

Contact information

15738867410

Online Message

Top