Precision casting with excellent quality

Integrated research and development, manufacturing, sales, and technical services of laboratory scientific instruments and intelligent equipment

National Consultation Hotline 15738867410

Integrated research and development, manufacturing, sales, and technical services of laboratory scientific instruments and intelligent equipment

National Consultation Hotline 15738867410

15738867410

Greenland Binhu International City (District 1), Erqi District, Zhengzhou City, Henan Province

Details

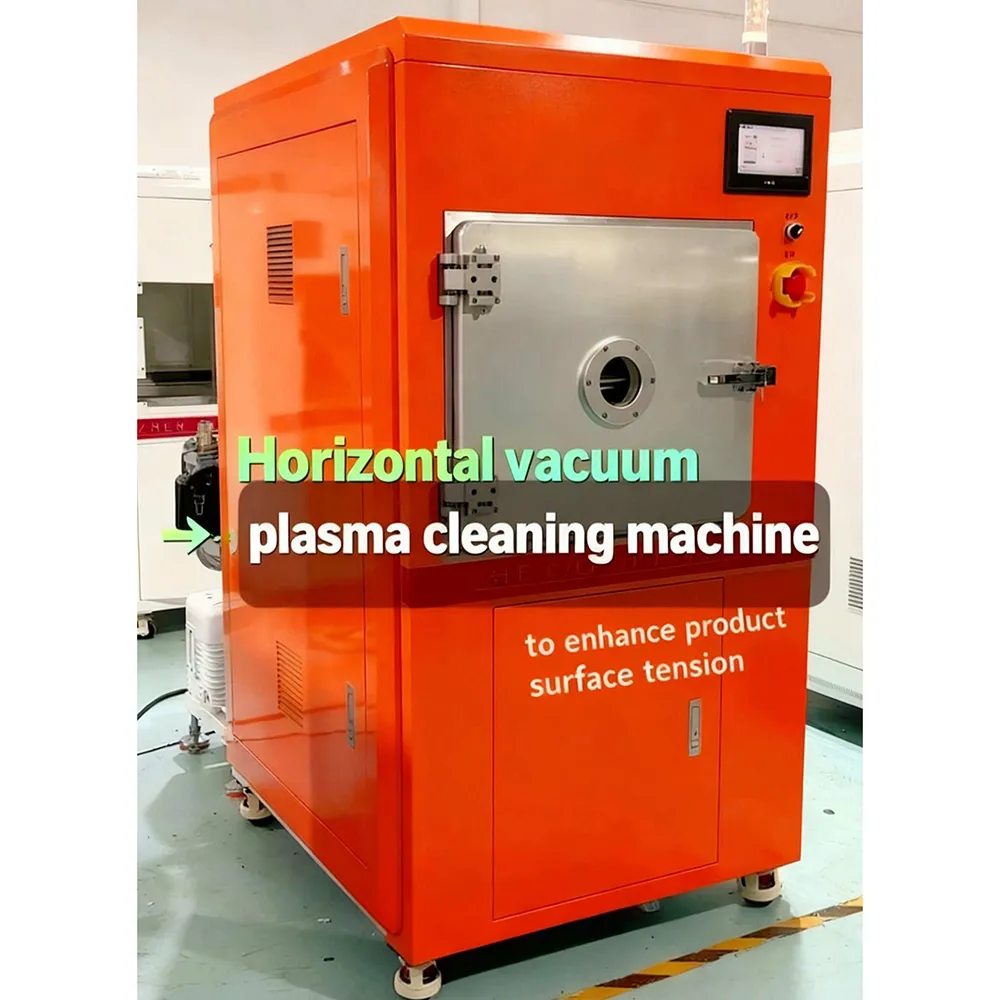

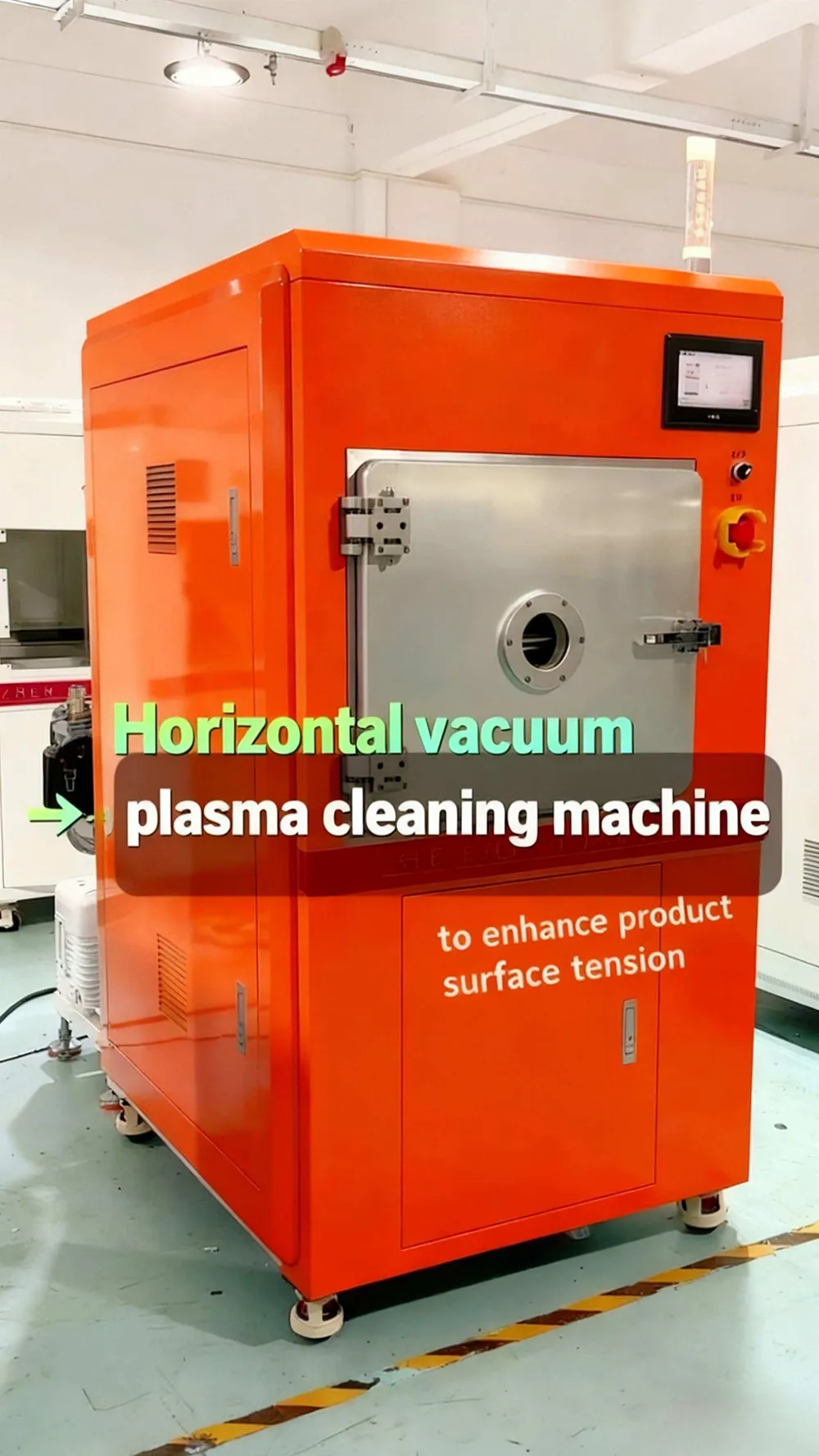

Horizontal vacuum plasma cleaning machine

Product Description

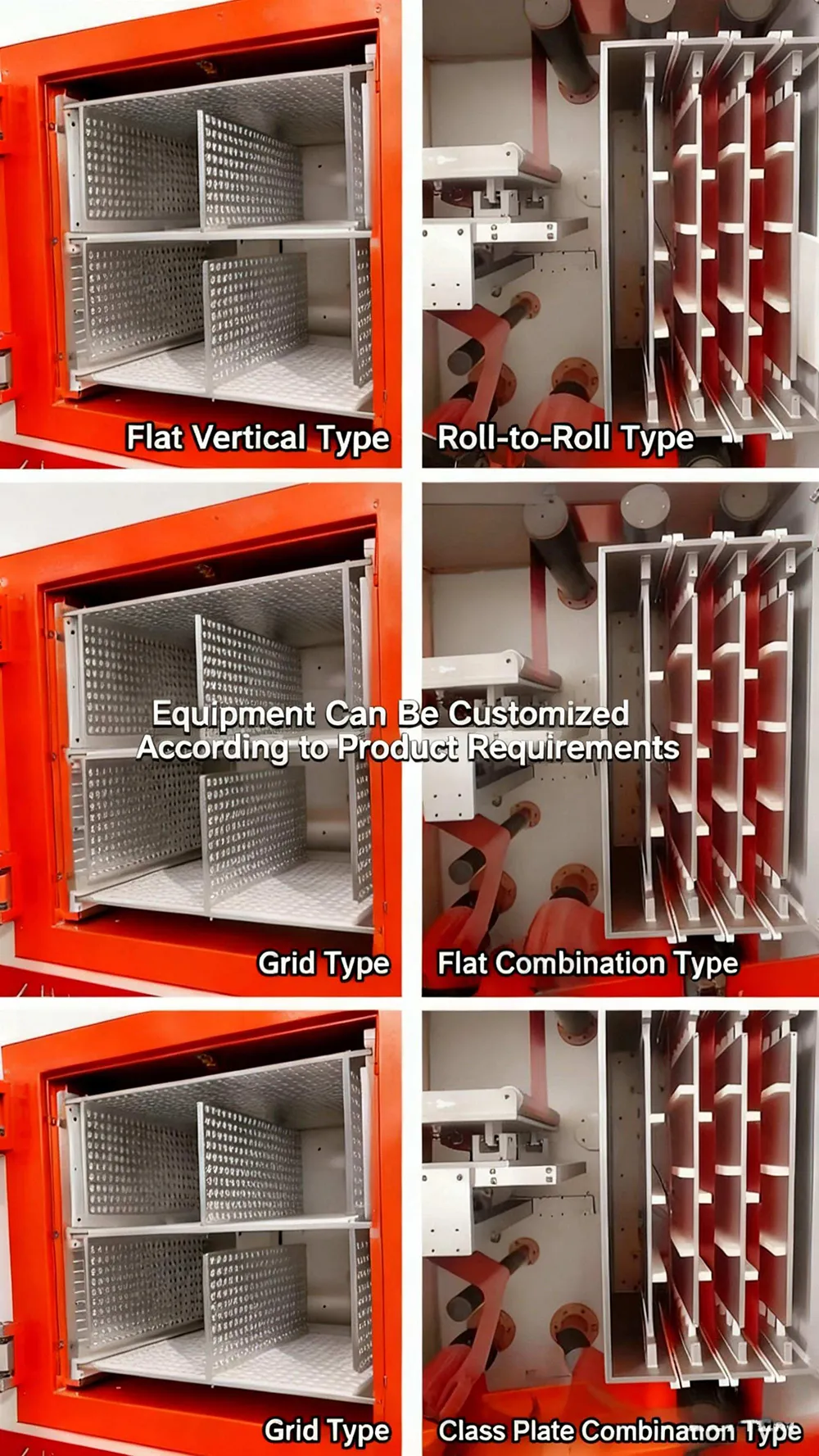

The laboratory plasma cleaner features a compact vertical design and takes up little space, making it suitable for use in universities, research institutes, and various laboratory environments. This equipment is primarily used for cleaning, activating, etching, and coating surfaces of materials such as semiconductors, precision electronic components, optical devices, biochips, ceramics, and metals. It effectively removes surface contaminants (such as organic matter, oxides, and particulates), improves material surface properties, and enhances the quality and reliability of subsequent processes (such as bonding, coating, and adhesive bonding).

Features

1.Efficient cleaning and activation

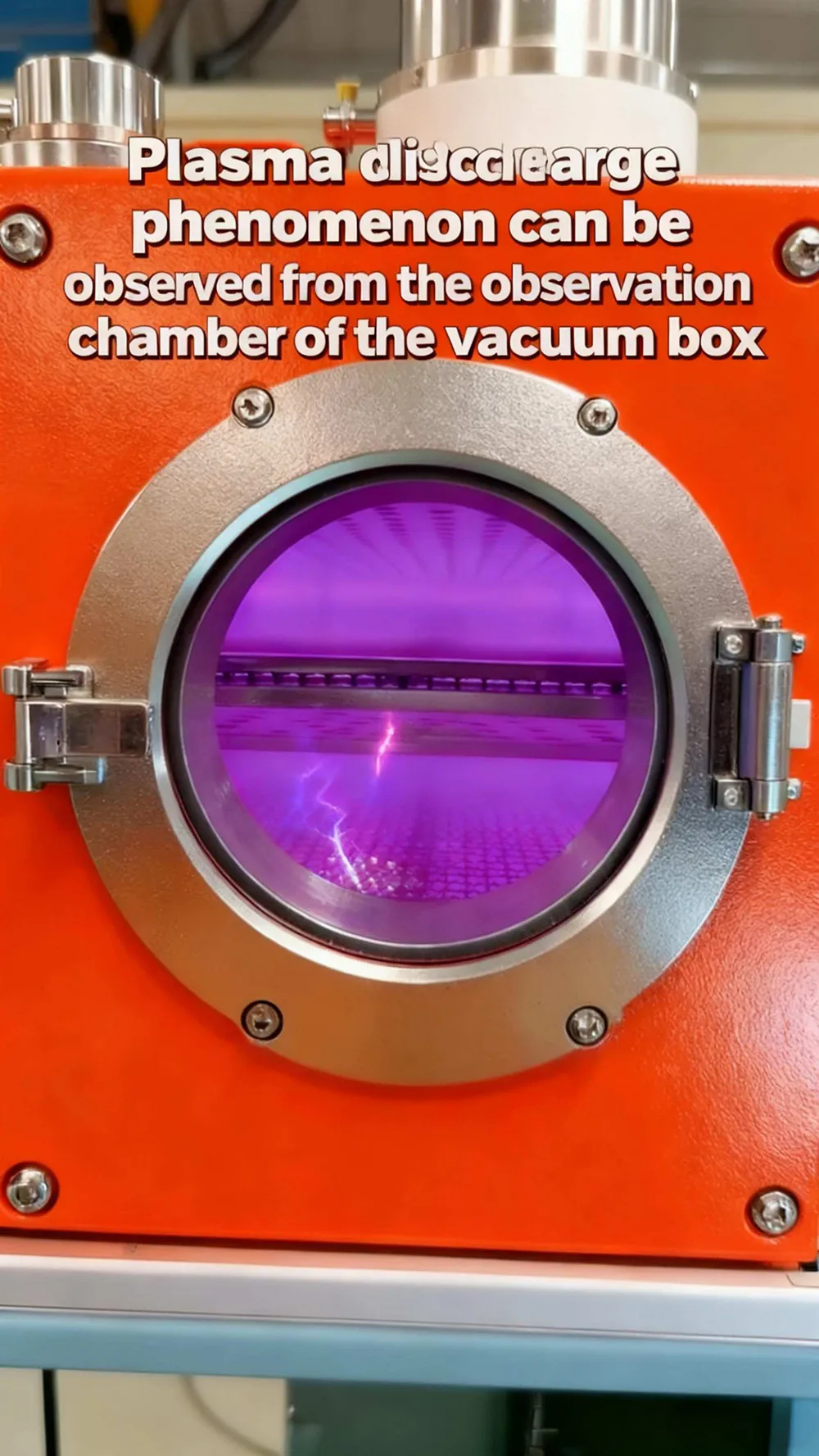

Using advanced plasma technology, through the dual effects of high-energy particle bombardment and chemical reaction, pollutants on the material surface are quickly removed, the surface activation energy is significantly increased, and the surface hydrophilicity or hydrophobicity and other properties are greatly improved.

2.Precise process control

Equipped with a high-precision gas flow control system, power regulation system and temperature monitoring system, it can accurately set and control plasma processing parameters (such as gas type, flow, power, processing time, chamber pressure, etc.) according to different material and process requirements to achieve process repeatability and stability.

3.Multi-function processing mode

It supports the single or mixed use of multiple gases (such as argon, oxygen, nitrogen, hydrogen, etc.), and can realize multiple processing modes such as cleaning, activation, etching, and deposition to meet the diverse needs of different materials and application scenarios.

4.Low damage treatment

The treatment process is carried out at low or room temperature, avoiding the damage caused by traditional wet chemical cleaning or high-temperature treatment to sensitive materials (such as polymer materials, biomaterials, etc.), ensuring that the original performance of the materials is not affected.

5.Easy and safe operation

It adopts a user-friendly human-machine interface design, the operation process is simple and intuitive, and the equipment is equipped with complete safety protection devices (such as overpressure protection, overheating protection, gas leakage alarm, etc.) to ensure the safety of operators and stable operation of the equipment.

6.Environmental protection and energy saving

No chemical solvents are required, which avoids the generation and discharge of chemical waste liquids and meets environmental protection requirements; the equipment has low energy consumption and low operating costs, and has good economic and environmental benefits.

Optional accessories

1. Gas flow controller : Achieve precise control and regulation of the flow of multiple gases to meet the precise gas flow requirements of complex processes.

2. Sample rotation device : It enables the sample to rotate evenly during the treatment process to ensure the uniformity of plasma treatment. It is suitable for samples with high requirements for treatment uniformity.

3. Vacuum measurement device : accurately measures the chamber vacuum degree in real time, providing reliable data support for precise control of process parameters.

4. Exhaust gas treatment device : purify the exhaust gas generated during the treatment process, remove harmful gases, and ensure the safety of the laboratory environment.

Application Areas

Semiconductor and electronics fields : cleaning before chip packaging, PCB board surface activation, removal of contaminants on the surface of electronic components, etc.

Optical field : cleaning of optical lenses before coating, optical fiber end face processing, surface cleaning of precision optical components, etc.

Biomedical field : biochip surface modification, medical catheter surface activation, implantable medical device surface treatment, etc.

Materials research areas : surface modification of nanomaterials, surface modification of polymer materials, surface activation of metal and ceramic materials, etc.

Other fields : surface treatment of aerospace precision parts, surface cleaning and activation of jewelry, surface treatment of cultural relics protection materials, etc.

QR code

Contact information

15738867410

Online Message

Top